In the energy and industrial sectors, capital projects are inherently complex and resource-intensive. When project execution fails, the consequences can be severe, ranging from financial losses and missed commercial operations dates to reputational damage and safety incidents. Yet, failure rarely arrives without notice. More often, it is preceded by a series of subtle but telling warning signs. These indicators, if identified early, offer a critical window of opportunity for intervention. Recognizing and responding to these early signals can mean the difference between a project that succeeds and one that spirals out of control.

This article outlines ten of the most common early warning signs that suggest a project is headed for trouble. Each is accompanied by key symptoms to watch for and proven strategies to mitigate risk and regain control. Whether you are a project owner, EPC contractor, construction manager, or investor, staying alert to these signs can help you safeguard your investment and deliver results with confidence.

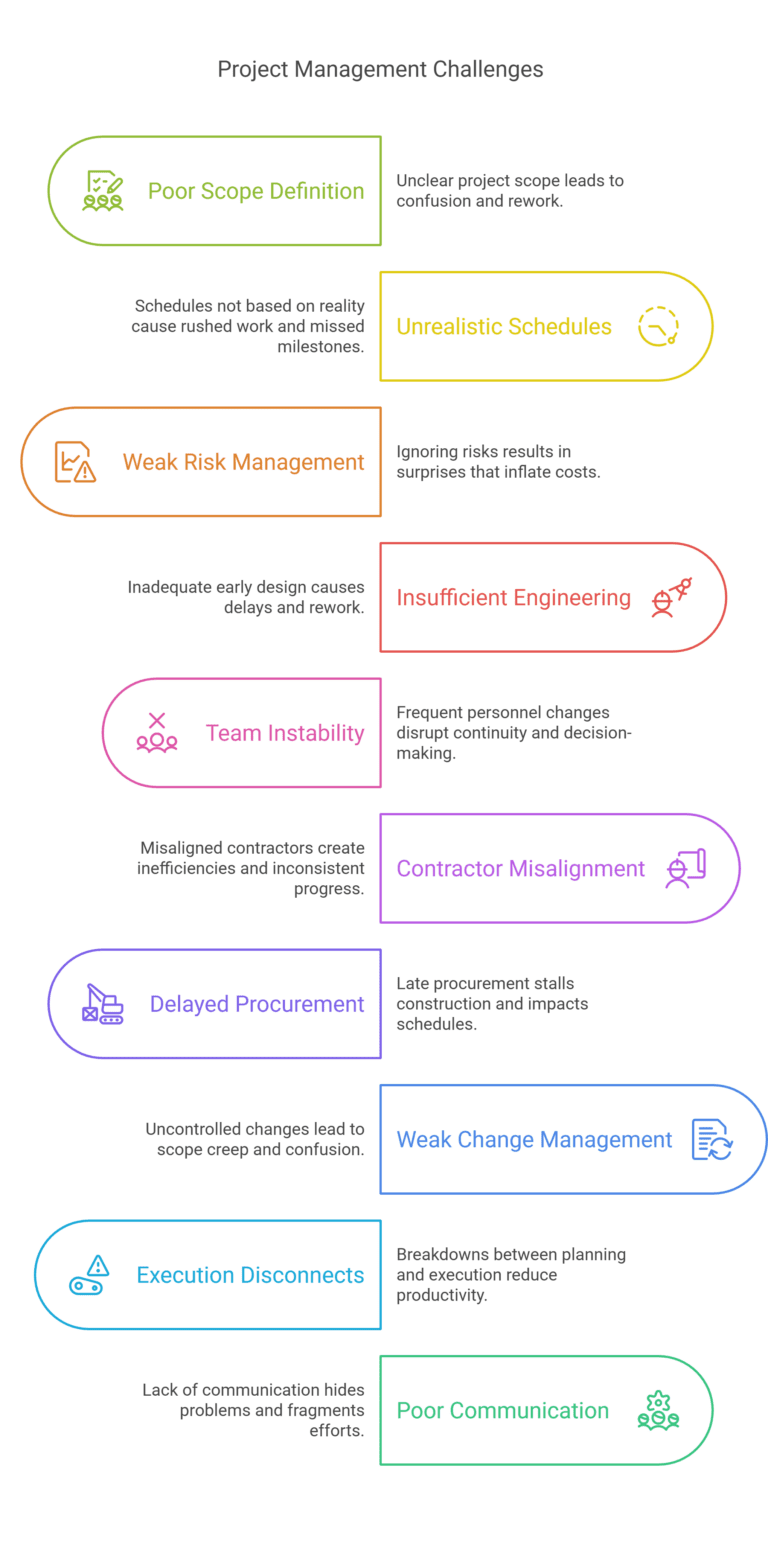

1. Poor Scope Definition

Poor scope definition undermines the foundation of any project. It introduces ambiguity into the entire delivery process, leading to disconnects between teams, rework, misaligned expectations, and ultimately missed milestones. Without a clear and shared understanding of what is in and out of scope, it becomes impossible to coordinate procurement, design, and construction effectively.

Symptoms:

- Vague project requirements or deliverables

- Frequent scope changes or debates

- High volume of RFIs (Requests for Information) during execution

Mitigation:

- Implement a structured front-end loading (FEL) process that ensures the scope is clearly defined before progressing

- Involve key stakeholders from all functional areas during scope development to achieve alignment and shared ownership

- Use work breakdown structures (WBS) to break the project into manageable, well-defined work packages that can be easily assigned and tracked

2. Unrealistic Schedules

Overly aggressive or politically motivated schedules often overlook the realities of field execution. Unrealistic scheduling results in sequential work being forced into parallel paths, loss of float, excessive overtime, and higher burnout among workers. It also weakens quality assurance

processes when activities are rushed.

Symptoms:

- Compressing durations without reducing scope

- Skipping critical planning steps to save time

- Reliance on overtime to stay on track

Mitigation:

- Develop schedules based on historical performance data and realistic productivity rates rather than optimism or external pressure

- Conduct quantitative schedule risk assessments (SRAs) to test schedule resilience under various scenarios

- Validate schedules using a bottoms-up approach, engaging field supervisors and subcontractors to ensure buy-in and constructability

3. Weak Risk Management Practices

Ignoring risks during the early planning stages leads to exposure during execution when the cost and effort to mitigate are highest. Projects that treat risk registers as static documents rather than living tools are often blindsided by predictable problems. Risk needs to be actively managed across cost, schedule, safety, and quality dimensions.

Symptoms:

- Risk registers are static or generic

- No assigned risk owners or mitigation plans

- Team unaware of risk priorities

Mitigation:

- Integrate risk management into every phase of the project, from estimating and scheduling to procurement and construction

- Conduct facilitated risk workshops with cross-functional teams to identify, quantify, and prioritize risks

- Assign clear ownership for each risk and monitor mitigation actions through regular reviews that tie risks to cost and schedule forecasts

4. Insufficient Front-End Engineering

Engineering is the blueprint for all downstream activities. When engineering is rushed or incomplete, it compromises procurement accuracy, disrupts field planning, and creates cascading delays. Field teams end up interpreting ambiguous drawings or waiting for design clarification, which leads to reduced productivity and costly errors.

Symptoms:

- Issued-for-construction (IFC) packages delayed or incomplete

- Frequent design changes during execution

- Field questions on basic design assumptions

Mitigation:

- Follow a gated design process such as FEL 1-3, with formal reviews and approvals at each phase

- Define specific design maturity milestones and track progress against them to ensure the project is ready for procurement and construction

- Conduct multidisciplinary constructability reviews with field leadership to validate designs before release

5. High Turnover or Team Instability

Continuity of personnel is crucial on complex projects. When leadership or subject matter experts rotate off the project midstream, institutional knowledge is lost, relationships are disrupted, and decision velocity slows. New team members often face steep learning curves that further

hinder productivity.

Symptoms:

- Key roles change mid-project

- Communication breakdowns or conflicting directions

- Repeated onboarding of new team members

Mitigation:

- Create robust onboarding processes and maintain comprehensive documentation to support knowledge transfer

- Identify critical roles and implement succession planning to minimize disruptions during staff transitions

- Foster a culture of accountability, inclusion, and engagement that encourages team retention and stability

6. Lack of Contractor Alignment

Contractors are extensions of the owner’s execution arm. When they are not aligned to shared goals and deliverables, progress stalls and conflict grows. Misaligned contractors often lack clarity on sequencing, hold competing priorities, or interpret scope differently, which undermines

collaboration.

Symptoms:

- Disputes over deliverables or scope interpretation

- Out-of-sequence work or idle crews

- Blame-shifting between contractors and owner teams

Mitigation:

- Develop a formal contractor integration strategy that includes onboarding, alignment workshops, and clear communication protocols

- Structure contracts to incentivize performance and mutual success rather than transactional compliance

- Hold regular alignment meetings that include leadership from all key contractor teams to resolve issues collaboratively

7. Delayed Procurement or Long-Lead Items

Late or inefficient procurement undermines schedule predictability. When long-lead items such as transformers, compressors, or custom-fabricated modules are delayed, entire work fronts may be paused or resequenced at great cost. Early procurement planning is often the linchpin of schedule success.

Symptoms:

- Late identification of long-lead equipment

- Vendor delays or missed submittal milestones

- Holding areas overflowing with unneeded materials while critical items are missing

Mitigation:

- Develop an integrated procurement plan that aligns with the overall project schedule and identifies critical-path items early

- Assign experienced procurement leads to high-value or complex packages and hold them accountable for schedule adherence

- Engage key vendors early in design to accelerate submittals, fabrication planning, and delivery timelines

8. Weak Change Management Process

Without a disciplined approach to managing change, project teams lose control of scope, cost, and commitments. Field personnel may act on verbal changes or assumptions, introducing inconsistencies and rework. Poorly documented changes also increase exposure during audits and disputes.

Symptoms:

- Untracked or unapproved changes implemented in the field

- Inconsistent documentation of scope changes

- Surprises during cost reviews or audits

Mitigation:

- Establish a formal Management of Change (MOC) process that includes documentation, impact assessment, approval, and communication workflows

- Ensure all proposed changes are evaluated for cost, schedule, safety, and constructability impacts before implementation

- Use integrated project controls systems to track approved changes and update forecasts accordingly

9. Field Execution Disconnects

Planning and execution must be fully integrated. When engineering and procurement teams operate in silos from field operations, gaps emerge that cause delays, resource idling, and work-arounds. Execution thrives on real-time information, alignment, and flexibility.

Symptoms:

- Engineering deliverables not constructible

- Tools, materials, or equipment unavailable when needed

- Miscommunications between field crews and supervisors

Mitigation:

- Conduct joint engineering and field reviews to verify constructability and resolve open questions before work begins

- Implement Advanced Work Packaging (AWP) to sequence work logically and ensure materials and drawings are ready at the right time

- Empower field supervisors to flag execution risks early and contribute to daily and weekly planning processes

10. Poor Communication and Reporting

Effective communication drives situational awareness and enables informed decision-making. Without a common understanding of progress, constraints, and emerging issues, project teams become reactive rather than proactive. Information silos and outdated reports mask problems until they escalate.

Symptoms:

- Key stakeholders unaware of critical issues

- Inconsistent or delayed reporting

- Conflicting data from different teams

Mitigation:

- Develop standardized reporting tools that provide transparent metrics across schedule, cost, quality, and safety

- Use visual dashboards to communicate key performance indicators (KPIs) in real time

- Facilitate structured coordination meetings between disciplines to align on priorities, status, and emerging concerns

Impact Matrix: Where the Damage Hits Hardest

Warning Sign | Cost Impact | Schedule Impact | Quality Impact |

Poor Scope Definition | High | High | Medium |

Unrealistic Schedules | Medium | High | High |

Weak Risk Management Practices | High | Medium | Medium |

Insufficient Front-End Engineering | High | High | High |

High Turnover or Team Instability | Medium | Medium | High |

Lack of Contractor Alignment | Medium | High | Medium |

Delayed Procurement or Long-Lead | High | High | Medium |

High | Medium | High | |

Field Execution Disconnects | Medium | High | High |

Poor Communication and Reporting | Medium | Medium | Medium |

Final Thoughts: Recognizing Trouble Early Saves Projects

Successful project execution in the industrial and energy sectors requires more than technical know-how. It demands vigilance, adaptability, and proactive leadership. While execution failures may seem sudden, they are almost always preceded by clear warning signs. Ignoring these signs allows problems to compound, while addressing them early gives teams a chance to course-correct and preserve value.

By embedding a culture of early detection, ongoing risk assessment, and open communication into your project delivery model, you strengthen your organization’s ability to navigate uncertainty and deliver results. These ten early warning signs, combined with an impact matrix, serve as a diagnostic framework for continuous monitoring and improvement.

Disclaimer

The information provided in this post is for reference purposes only and is intended to serve as a guide to highlight key topics, considerations, and best practices. It does not constitute professional advice or a substitute for consulting regarding specific projects or circumstances. Readers are encouraged to evaluate their unique project needs and seek tailored advice where necessary. Please Contact Us to discuss your particular project.