Midstream projects are a cornerstone of the energy value chain, connecting upstream production with downstream processing and distribution. These critical developments, ranging from pipelines and storage facilities to processing plants, demand tailored execution strategies to address their unique challenges, including market-driven constraints, tighter timelines, and cost-efficiency requirements. Unlike the expansive approaches seen in downstream mega projects, midstream execution thrives on fit for purpose methodologies that emphasize efficiency, modularity, and streamlined operations.

This article dives into the defining elements of successful fit-for-purpose project execution in the midstream sector, focusing on attributes such as speed, standardization, and risk management. We highlight the importance of adopting lifecycle EPC execution to ensure consistency, predictability, and alignment with operational objectives. Alongside these strategies, we uncover lessons learned from the field and share best practices such as advanced work packaging, front end planning, and construction focused execution. By applying these insights, stakeholders can confidently navigate the complexities of midstream development while achieving excellence in efficiency, cost control, and project delivery.

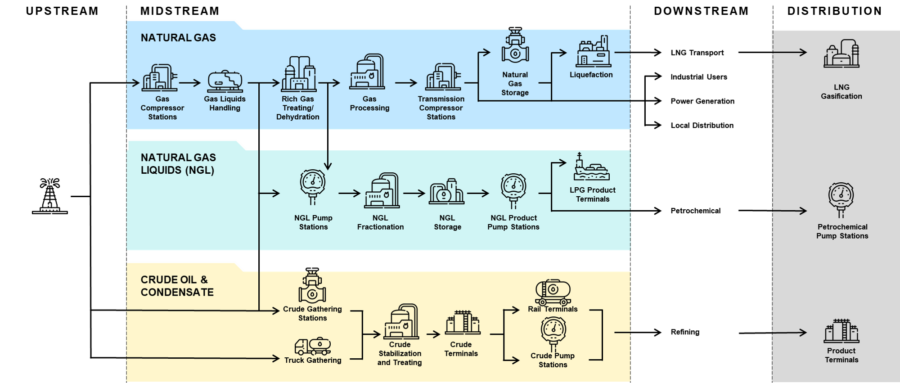

What is Midstream?

Midstream refers to the segment of the energy industry that involves the transportation, storage, and processing of oil, natural gas, and other hydrocarbons between the upstream (exploration and production) and downstream (refining and distribution) sectors.

Key Components of Midstream

Transportation:

Pipelines: Used to move oil, gas, and refined products over long distances efficiently.

Rail, Truck, and Ships: Alternative transport modes for regions without pipeline infrastructure.Storage:

Tanks and terminals store crude oil, natural gas, and refined products to manage supply and demand fluctuations.Processing:

Gas Processing Plants: Remove impurities (e.g., sulfur, water, and carbon dioxide) and extract natural gas liquids (NGLs) like propane and butane.

Fractionation: Separates NGLs into individual products for commercial use.

Purpose of Midstream

- Linking Upstream and Downstream: It bridges the gap by transporting and preparing raw hydrocarbons for refining or distribution.

- Maintaining Supply Chain Flow: Ensures smooth delivery of energy products from production fields to consumers.

- Market Responsiveness: Provides the infrastructure to adapt to changing supply and demand, enabling energy markets to function efficiently.

Midstream is critical for ensuring energy reliability and efficiency across the value chain.

Fit-for-Purpose Project Execution: The Hallmark of Midstream Success

In the midstream sector, the ability to adopt a fit-for-purpose execution strategy stands as the hallmark of project success. This approach tailors methodologies, designs, and processes to the unique demands of midstream projects, which often involve smaller scales, tighter budgets, and market-driven timelines. By focusing on practicality, efficiency, and value, fit-for-purpose execution ensures that resources are optimized and unnecessary complexity is avoided.

Key Principles of Fit-for-Purpose Execution

- Customized Solutions for Specific Needs:

Every midstream project has unique challenges, whether it involves pipeline construction, storage facility installation, or processing plant development. A fit-for-purpose strategy avoids generic methodologies, focusing instead on tailored solutions that address specific requirements and objectives. - Optimized Resource Allocation:

Fit-for-purpose execution emphasizes deploying resources where they matter most. Specialized teams, strategic procurement, and efficient workflows ensure that critical-path activities receive priority, preventing delays and cost overruns. - Scalability for Dynamic Conditions:

Midstream projects operate in volatile markets, requiring infrastructure and systems that can adapt to changing capacities or demands. Scalable solutions, such as modular components or adjustable throughput systems, provide long-term flexibility without unnecessary upfront costs. - Prioritization of Practicality Over Complexity:

Simplified designs, lean workflows, and streamlined documentation ensure that the project remains focused on delivering operationally aligned results. This avoids overdesign, reduces administrative overhead, and accelerates execution timelines. - Value-Driven Decision-Making:

Fit-for-purpose strategies prioritize high-impact deliverables, such as early procurement of long-lead items, achieving permitting milestones, and ensuring readiness for construction. These critical actions prevent bottlenecks and enhance overall project momentum.

Benefits of Fit-for-Purpose Execution

- Cost Efficiency: By eliminating waste and focusing only on necessary processes, fit-for-purpose execution reduces overall project costs.

- Timely Delivery: Streamlining workflows and prioritizing critical activities ensures projects meet or exceed timeline expectations.

- Operational Excellence: The final deliverables align directly with real-world operational needs, avoiding overdesign while maintaining functionality and safety.

- Risk Mitigation: A focused approach minimizes exposure to unnecessary risks by simplifying execution and enhancing adaptability.

Key Practices for Fit-for-Purpose Execution

- Streamlined Documentation: Avoid overburdening teams with excessive administrative tasks; maintain a focus on execution.

- Value Engineering: Regularly review designs and procurement strategies to identify cost-saving opportunities without sacrificing quality.

- Stakeholder Engagement: Involve all stakeholders early in the process to align project goals and operational requirements from the outset.

- Data-Driven Adjustments: Leverage real-time analytics and historical insights to make informed decisions and adapt plans as needed.

Why Fit-for-Purpose Execution is Central to Midstream Success

The midstream sector’s unique challenges—market-driven demands, cost constraints, and smaller project scopes—make fit-for-purpose execution not just a strategy but a necessity. By tailoring every aspect of a project to its specific needs, stakeholders can ensure maximum efficiency, faster delivery, and sustainable success.

This approach is not merely an operational adjustment; it is a mindset that defines how midstream projects are conceptualized, planned, and executed. It enables organizations to adapt to the evolving energy landscape while maintaining a competitive edge, setting the standard for excellence in midstream execution.

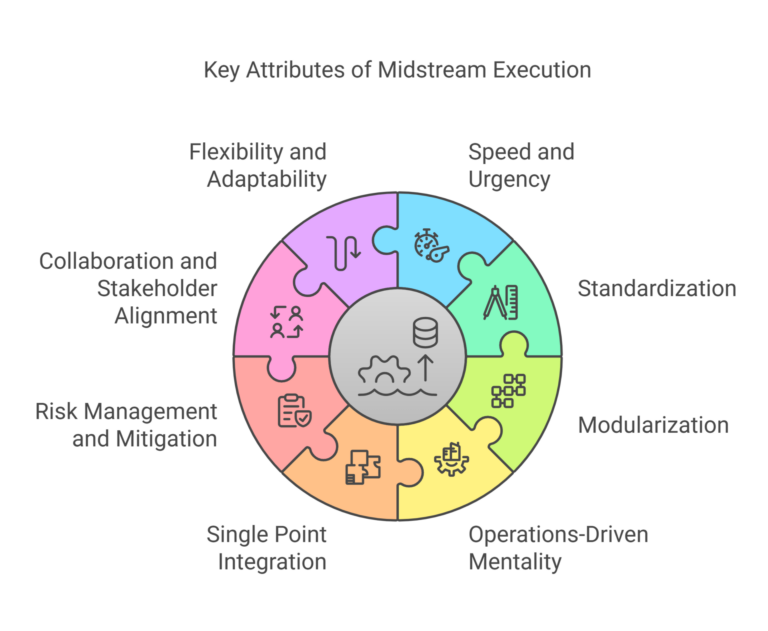

Attributes of Successful Midstream Execution

Midstream execution demands a strong emphasis on efficiency, repeatability, and streamlined processes. The ability to deliver projects on time and within budget hinges on the incorporation of practices that align with these principles. For example, a successful project might leverage standardized designs and modular construction to cut costs and reduce on-site delays. Below is a detailed exploration of the key attributes that drive successful midstream execution:

Speed and Urgency

Midstream projects often face intense market pressures, such as fluctuating commodity prices and evolving demand dynamics, which demand rapid mobilization and execution. Accelerating decision-making processes, minimizing bottlenecks, and prioritizing critical-path activities are essential to maintain momentum. Strategies to ensure speed without compromising quality include:

- Implementing fast-track project delivery models.

- Encouraging real-time communication between stakeholders.

- Utilizing advanced project management software for enhanced scheduling and progress tracking.

Standardization

Consistency is a cornerstone of efficient midstream execution. By avoiding the reinvention of processes and leveraging proven templates, designs, and workflows, project teams can save significant time while reducing errors. Key practices include:

- Developing and maintaining a library of standardized design packages.

- Utilizing consistent procurement strategies to streamline material delivery.

- Training teams on standardized procedures to ensure uniformity across multiple projects.

Modularization

Modular construction techniques have become indispensable in midstream projects due to their ability to minimize on-site complexities and accelerate timelines. Prefabricated modules are manufactured off-site, reducing labor costs, on-site risks, and environmental disruptions. Key benefits and strategies include:

- Faster project completion through parallel module fabrication and site preparation.

- Improved quality control in controlled factory environments.

- Simplified logistics with well-coordinated transportation and assembly plans.

Operations-Driven Mentality

Successful midstream projects are designed with operational efficiency in mind. This means aligning project decisions with the end goals of reliability, maintainability, and safety. Engaging operations teams early in the project lifecycle ensures designs are practical and meet operational needs. Best practices include:

- Conducting operability and maintainability reviews during the design phase.

- Designing facilities with clear and efficient process flows.

- Incorporating automation and data integration systems to enhance long-term operational performance.

Single Point Integration

A cohesive execution strategy is vital for minimizing contractor interfaces and ensuring alignment across all project phases. Establishing a single point of accountability, often through an integrated project management team or EPC (Engineering, Procurement, and Construction) contractor, promotes seamless communication and decision-making. Advantages include:

- Simplified project coordination, reducing delays and miscommunication.

- Clear accountability for project outcomes, enhancing stakeholder confidence.

- Streamlined change management processes to address deviations effectively.

Risk Management and Mitigation

Proactively identifying and managing risks ensures smoother project execution and reduces costly surprises. Effective risk management practices include:

- Establishing a comprehensive risk register to track and address potential issues.

- Conducting scenario planning to prepare for market fluctuations, regulatory changes, or environmental challenges.

- Utilizing contingency planning and allocating budget reserves for unforeseen events.

Collaboration and Stakeholder Alignment

Ensuring alignment among all stakeholders—from owners to contractors and local communities—helps prevent miscommunication and delays. Approaches to foster collaboration include:

- Regular progress reviews and alignment meetings with all stakeholders.

- Clearly defining roles, responsibilities, and expectations in contracts and project charters.

- Utilizing shared project management platforms for transparency in schedules, budgets, and deliverables.

Flexibility and Adaptability

The ability to adjust to changing project conditions, such as market dynamics or weather delays, is essential for success. Key enablers include:

- Agile project management methodologies to pivot when necessary.

- Flexible contracts that accommodate scope adjustments and unforeseen challenges.

- Real-time monitoring tools to quickly identify and respond to deviations.

Summary

Attribute | Key Practices | Benefits |

Speed and Urgency | – Fast-track delivery models | – Captures market opportunities |

Standardization | – Use of standardized designs | – Reduces errors |

– Off-site fabrication | – Accelerates timelines | |

Operations-Driven Design | – Operability reviews | – Ensures reliability |

Single Point Integration | – Unified accountability | – Reduces miscommunication |

Risk Management and Mitigation | – Establish risk registers | – Proactively addresses uncertainties |

Collaboration and Stakeholder Alignment | – Regular progress reviews | – Builds trust |

Flexibility and Adaptability | – Agile project management methodologies | – Enables quick responses to changing conditions |

Why Midstream Projects Require a Different Approach

Midstream projects, encompassing activities such as pipeline construction, storage facilities, and processing plants, differ fundamentally from the vast scale and complexity of upstream (exploration and production) or downstream (refining and distribution) developments. These differences necessitate a tailored approach to execution that reflects their unique characteristics and challenges. Below is a detailed exploration of why midstream projects demand distinct strategies:

Project Scale

While midstream projects are critical to the energy value chain, they are typically smaller in scope compared to the massive scale of upstream developments or downstream refineries. These differences in scale demand:

- Efficient Execution Strategies: Focused project management that minimizes overhead and streamlines processes.

- Simplified Workflows: Lean project frameworks that prioritize critical activities without unnecessary complexity.

- Resource Optimization: Maximizing output with smaller teams and reduced budgets.

For example, a midstream pipeline project may span hundreds of miles but involves less intricate infrastructure compared to a multi-billion-dollar offshore platform.

Market Sensitivity

Midstream projects are highly influenced by market dynamics, such as fluctuating demand, commodity prices, and regional growth patterns. These market forces drive the need for:

- Faster Delivery: Projects must be executed quickly to capture market opportunities and respond to supply chain shifts.

- Scalable Designs: Flexible designs that can adapt to market changes, such as increasing capacity or adding connections to new supply sources.

- Data-Driven Decisions: Leveraging real-time market analytics to guide project prioritization and resource allocation.

For instance, the timing of a natural gas pipeline project might be critical to supply a growing market during peak demand seasons.

Cost Constraints

Budgets for midstream projects are often tighter compared to upstream or downstream developments. Companies must deliver high-value results without overspending. To achieve this:

- Creative Approaches: Employing innovative construction techniques, such as modularization or trenchless pipeline installation.

- Value Engineering: Identifying cost-saving measures during the design phase without compromising functionality or safety.

- Vendor Negotiation: Building partnerships with suppliers to secure competitive pricing and favorable terms.

An example is the use of pre-fabricated compressor stations, which significantly reduce costs and on-site construction timelines.

Operational Integration

Midstream infrastructure serves as the critical link between upstream production and downstream consumption, necessitating seamless alignment with both ends of the value chain. This operational integration requires:

- Close Collaboration: Coordinating with upstream and downstream stakeholders to ensure alignment of schedules, capacities, and specifications.

- Reliability Focus: Designing infrastructure that ensures continuous and efficient flow, minimizing bottlenecks or disruptions.

- Data Sharing: Implementing systems that integrate real-time data from upstream and downstream operations for better decision-making.

For instance, a gas processing facility must align its output specifications to the downstream customer’s requirements, such as gas quality for power generation or export.

Leaner, Agile Strategies

Applying methodologies designed for mega-projects to midstream developments can lead to inefficiencies, delays, and increased costs. Midstream projects benefit from leaner, more agile strategies that emphasize practicality over complexity:

- Streamlined Decision-Making: Fewer decision layers and shorter approval cycles to maintain project momentum.

- Simplified Project Controls: Avoiding overly detailed systems that may be unnecessary for mid-sized projects, instead focusing on high-impact metrics.

- Flexible Execution Plans: Allowing for iterative adjustments based on project progress or external changes.

For example, an iterative approach to pipeline routing allows teams to adapt to permitting challenges or landowner negotiations without significant delays.

Full Lifecycle EPC Execution: A Cornerstone of Midstream Project Success

In midstream projects, adopting a full lifecycle EPC (Engineering, Procurement, and Construction) execution approach is critical to achieving consistency, predictability, and alignment with project objectives. This method integrates all phases of the project, from design to handover, under a single cohesive strategy, which is particularly suited to the unique demands of midstream development. Below is an expanded exploration of how lifecycle EPC execution supports midstream project success:

Speed to Market

In the competitive midstream sector, rapid delivery is essential to capitalize on market opportunities and respond to demand fluctuations. A lifecycle EPC approach accelerates schedules by:

- Streamlining Interfaces: Consolidating engineering, procurement, and construction under one framework to reduce handoffs and delays.

- Concurrent Execution: Overlapping phases, such as procurement and construction, to optimize timelines without compromising quality.

- Integrated Scheduling: Leveraging advanced project planning tools to identify and resolve critical path issues early.

For example, fast-track EPC delivery can enable a natural gas pipeline to meet winter heating demand, ensuring profitability and market relevance.

Cost Certainty

Midstream projects often operate within tight budgets, making accurate cost management a top priority. Lifecycle EPC execution delivers cost certainty by:

- Early Estimation Accuracy: Developing precise cost estimates during the front-end engineering and design (FEED) phase to set realistic budgets.

- Procurement Optimization: Leveraging bulk purchasing and long-term supplier agreements to secure cost savings.

- Change Control Discipline: Implementing robust systems to manage scope changes and avoid unexpected cost escalations.

By aligning cost controls across all project phases, lifecycle EPC minimizes surprises and ensures financial feasibility.

Risk Mitigation

The integration of engineering, procurement, and construction under a single execution strategy reduces fragmentation and creates opportunities for proactive risk management:

- Unified Responsibility: A single EPC contractor takes accountability for all project aspects, reducing coordination risks between multiple stakeholders.

- Integrated Risk Planning: Identifying and addressing risks early, such as material shortages, regulatory challenges, or weather delays.

- Safety and Compliance: Ensuring that safety and regulatory requirements are seamlessly embedded into all stages of the project.

For instance, a lifecycle EPC approach allows for better coordination in pipeline construction through environmentally sensitive areas, reducing permitting delays and reputational risks.

Standardized Deliverables

Consistency in deliverables is critical for midstream projects, where alignment between upstream and downstream operations depends on predictable outcomes. Lifecycle EPC execution achieves this through:

- Standardized Documentation: Unified templates and formats for engineering designs, procurement specifications, and construction reports ensure clarity and alignment.

- Repeatable Processes: Leveraging best practices and templates across projects to reduce variability and improve efficiency.

- Enhanced Communication: Providing clear and consistent information to stakeholders, improving collaboration and decision-making.

For example, standardizing valve specifications across multiple pipelines simplifies maintenance and reduces long-term operational costs.

Why Lifecycle EPC Execution is Key to Midstream Success

Unlike mega-projects with more extended timelines and broader scopes, midstream projects require focused, efficient, and coordinated execution to meet tighter schedules, budgets, and market-driven demands. Lifecycle EPC execution aligns all project phases under a single strategy, ensuring:

- Seamless transitions between engineering, procurement, and construction activities.

- A focus on practical, results-driven execution tailored to midstream infrastructure.

- The flexibility to adapt to changing project needs while maintaining speed, cost, and quality objectives.

By adopting a lifecycle EPC execution approach, midstream project teams can deliver consistent, high-quality results that meet market demands, enhance operational integration, and drive long-term success. This comprehensive approach is not just a methodology but a strategic enabler for achieving midstream execution excellence.

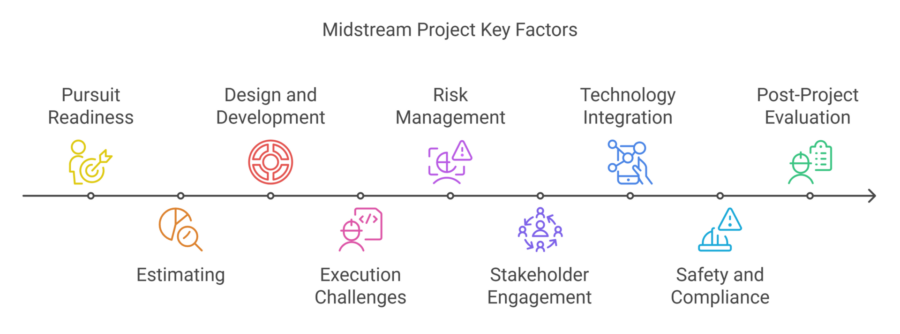

Midstream Execution Lessons Learned

Midstream projects provide numerous insights and lessons applicable across the sector:

Pursuit Readiness

- Develop a thorough understanding of the project scope and objectives to set a strong foundation for execution.

- Formulate a vendor and equipment strategy early to prevent delays during procurement.

- Engage with key stakeholders and regulatory bodies early to identify and address permitting or compliance challenges.

- Conduct market analysis to ensure project timing aligns with market demand and supply chain availability.

Estimating

- Create comprehensive, integrated execution plans that encompass all phases of the project lifecycle. Accurate estimates reduce the likelihood of costly overruns.

- Ensure clarity and transparency in estimates to align stakeholder expectations and maintain project momentum.

- Incorporate risk contingencies and conduct scenario analysis to prepare for potential changes in project scope or market conditions.

- Leverage benchmarking data from similar projects to validate cost estimates and identify potential inefficiencies.

Design and Development

- Assign teams early and establish a readiness plan to ensure alignment, ownership, and familiarity with project objectives.

- Address ambiguities in project plans and designs proactively to avoid delays caused by misaligned expectations or unclear deliverables.

- Emphasize operational alignment during design, ensuring that end-users’ requirements and maintenance considerations are integrated.

- Leverage modular design principles to accelerate timelines and reduce on-site complexities.

- Perform constructability reviews to identify and resolve potential design conflicts or challenges before construction begins.

Execution Challenges

- Align stakeholder expectations with project realities through transparent communication and regular progress updates.

- Mitigate delays by fostering a sense of urgency and ensuring clear accountability across teams and contractors.

- Monitor critical path activities closely and allocate resources strategically to avoid bottlenecks.

- Implement robust change management practices to address scope changes efficiently and minimize disruption.

- Maintain flexibility in execution plans to adapt to unforeseen circumstances, such as weather-related delays or supply chain disruptions.

Risk Management

- Develop a comprehensive risk register to identify, assess, and mitigate risks across all project phases.

- Engage multidisciplinary teams during risk assessments to ensure all potential challenges are considered.

- Establish contingency plans and allocate appropriate buffers in cost and schedule to address unexpected events.

- Regularly update risk assessments to reflect evolving project conditions or market dynamics.

Stakeholder Engagement

- Build strong relationships with local communities, regulatory bodies, and other external stakeholders to ensure smooth project approvals and execution.

- Foster a culture of collaboration among contractors, suppliers, and project teams to enhance communication and trust.

- Clearly define roles, responsibilities, and expectations for all stakeholders to avoid conflicts or misalignment.

Technology Integration

- Leverage advanced project management and collaboration tools to improve scheduling, communication, and tracking.

- Use digital modeling and simulation tools to optimize designs and assess operational efficiency before construction begins.

- Incorporate real-time monitoring systems to track progress and identify potential issues proactively.

Safety and Compliance

- Prioritize safety training and protocols to minimize risks during construction and operation.

- Conduct regular audits to ensure compliance with regulatory and environmental requirements.

- Design infrastructure with sustainability and environmental impact in mind to align with long-term industry trends and expectations.

Post-Project Evaluation

- Conduct thorough post-project reviews to capture lessons learned, focusing on successes, challenges, and areas for improvement.

- Document and standardize best practices for future projects to improve consistency and efficiency.

- Engage all stakeholders in the review process to gather diverse perspectives and ensure comprehensive feedback.

Summary

Category | Lessons Learned | Impact |

Pursuit Readiness | – Thoroughly define project scope and objectives. | – Prevents delays and misalignment. |

Estimating | – Develop integrated, realistic execution plans. | – Reduces cost overruns. |

Design and Development | – Assign teams early and ensure readiness plans are in place. | – Avoids rework and delays. |

Execution Challenges | – Foster urgency and accountability to meet critical path milestones. | – Minimizes delays. |

Risk Management | – Develop a comprehensive risk register and update it regularly. | – Mitigates unexpected disruptions. |

Stakeholder Engagement | – Build strong relationships with communities and regulatory bodies to ease approvals. | – Reduces conflicts. |

Materials Management | – Procure critical materials and equipment early to mitigate supply chain risks. | – Avoids delays caused by material shortages. |

Technology Integration | – Leverage advanced project management tools for scheduling and progress tracking. | – Enhances decision-making. |

Safety and Compliance | – Prioritize safety training and audits throughout the project lifecycle. | – Reduces risks and legal challenges. |

Post-Project Evaluation | – Conduct comprehensive reviews to document lessons learned. | – Supports continuous improvement. |

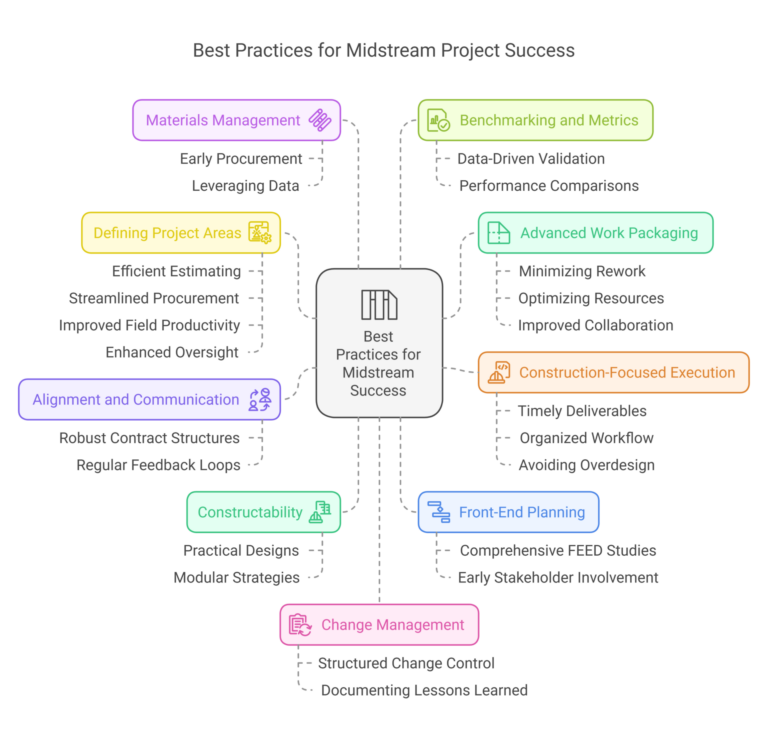

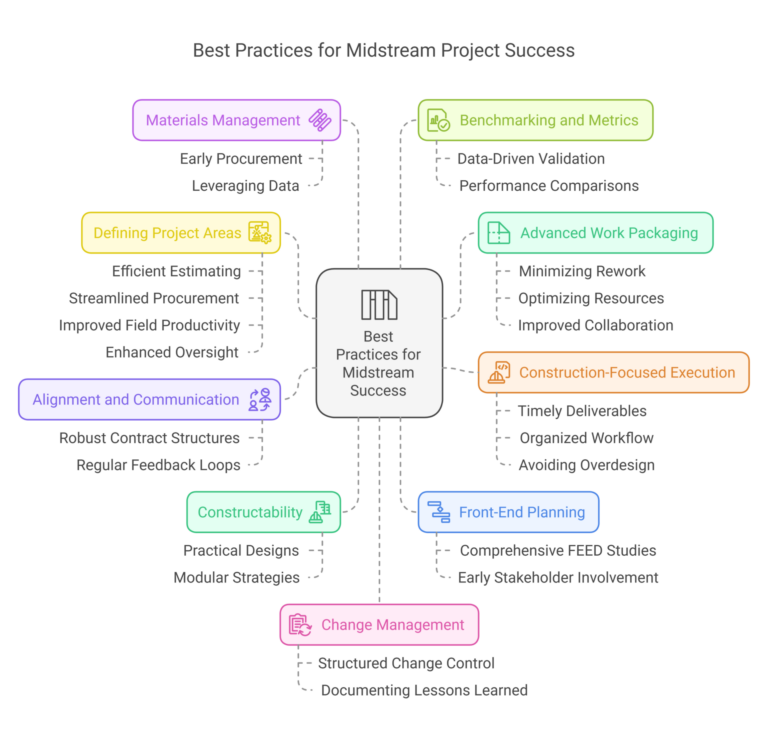

Best Practices for Midstream Success

Implementing best practices is pivotal to achieving project excellence. Core practices include:

Advanced Work Packaging (AWP)

Integrating planning across engineering, procurement, and construction enhances repeatability and efficiency, ensuring a seamless flow of information and resources. Benefits include:

- Minimizing Rework: Breaking down projects into structured work packages that are deliverable-focused ensures all components are ready before field execution.

- Optimizing Resources: Coordinating schedules and resource allocation reduces delays and enhances productivity.

- Improved Collaboration: Real-time visibility into package progress fosters better communication between teams.

Alignment and Communication

Clear and continuous alignment among stakeholders is essential for smooth execution. Key practices include:

- Robust Contract Structures: Tailoring contracts to project goals with clear scopes, deliverables, and responsibilities minimizes disputes and misunderstandings.

- Regular Feedback Loops: Holding progress reviews, alignment meetings, and milestone check-ins ensures ongoing communication and adjustment as needed.

Constructability

Designing with construction in mind streamlines field operations and minimizes on-site challenges:

- Practical Designs: Engineering teams must prioritize simplicity and functionality, avoiding overly complex solutions that hinder construction.

- Modular Strategies: Shifting labor-intensive tasks to controlled environments off-site reduces risks, enhances quality control, and shortens on-site timelines.

Front-End Planning (FEP)

Effective front-end planning sets the stage for project success by addressing potential challenges early:

- Comprehensive FEED Studies: Detailed front-end engineering and design studies create a clear roadmap, identifying risks and mitigation strategies.

- Early Stakeholder Involvement: Aligning objectives and expectations early minimizes friction during execution and facilitates smoother decision-making.

Materials Management

Efficient materials management mitigates supply chain risks and ensures timely availability of critical resources:

- Early Procurement: Securing long-lead and standard engineered equipment during the early phases prevents delays caused by supply chain disruptions.

- Leveraging Data: Using historical project data to refine procurement strategies enhances predictability and accuracy in material planning.

Benchmarking and Metrics

Tracking performance and using data analytics are crucial for validating project estimates and identifying areas for improvement:

- Data-Driven Validation: Historical and predictive analytics refine cost estimates, improve schedule accuracy, and identify risks early.

- Performance Comparisons: Comparing key performance indicators (KPIs) across projects reveals trends and areas requiring attention, driving continuous improvement.

Change Management

Managing changes effectively prevents scope creep and minimizes disruptions:

- Structured Change Control: A well-defined process for evaluating and implementing changes ensures minimal impact on timelines and budgets.

- Documenting Lessons Learned: Insights from managing changes enhance future projects, fostering a culture of continuous learning and process improvement.

Defining Project Areas

Breaking projects into manageable areas enhances efficiency, predictability, and control:

- Efficient Estimating: Historical data provides a reliable basis for cost and schedule predictions, reducing uncertainty.

- Streamlined Procurement: Managing areas as distinct entities simplifies purchasing and coordination.

- Improved Field Productivity: Standardization across areas can boost productivity by up to 25%.

- Enhanced Oversight: Clearly defined areas improve quality control and safety management.

Construction-Focused Execution

Prioritizing construction readiness ensures that projects progress without delays or cost overruns:

- Timely Deliverables: Ensuring critical drawings, materials, and equipment are available as needed prevents bottlenecks.

- Organized Workflow: Systematic work planning clarifies responsibilities and improves accountability.

- Avoiding Overdesign: Striking a balance between meeting current requirements and maintaining flexibility for future needs avoids unnecessary complexity and cost increases.

Summary

Practice | Description | Key Benefit |

Advanced Work Packaging (AWP) | Integrates planning across engineering, procurement, and construction phases | – Enhances repeatability |

Alignment and Communication | Establishes robust contract structures and fosters ongoing alignment through regular feedback loops | – Reduces misunderstandings |

Conducts detailed FEED studies, involves stakeholders early, and identifies risks at the outset | – Aligns objectives | |

Constructability | Focuses on construction-friendly designs, modular strategies, and pre-fabrication techniques | – Streamlines field operations |

Materials Management | Implements early procurement of critical equipment and uses historical data to enhance material planning | – Prevents supply chain risks |

Benchmarking and Metrics | Uses historical data and predictive analytics to validate estimates and track performance | – Drives continuous improvement |

Change Management | Establishes structured processes for handling changes and incorporates lessons learned into future projects | – Minimizes disruptions |

Defining Project Areas | Breaks projects into manageable areas for efficient resource allocation and better oversight | – Enhances productivity |

Prioritizes timely delivery of critical drawings and materials while balancing current needs with future flexibility | – Prevents delays | |

Technology Integration | Leverages real-time monitoring systems, digital modeling, and project management tools | – Increases efficiency |

Safety and Compliance | Embeds safety protocols, regular audits, and sustainability measures into all phases | – Reduces risks |

Conclusion

Midstream execution requires a disciplined, tailored approach that addresses the sector’s unique demands. By focusing on speed to market, cost control, and operational integration, stakeholders can ensure projects meet tight schedules and budgets while delivering high-quality outcomes. This article has highlighted the critical attributes of successful midstream execution, such as modular construction, standardized processes, and advanced risk management strategies. It also emphasized the value of full lifecycle EPC execution for seamless transitions between engineering, procurement, and construction phases.

The lessons learned from past midstream projects underscore the importance of stakeholder alignment, efficient materials management, and data-driven decision-making. Best practices such as advanced work packaging, front-end planning, and benchmarking provide a foundation for continuous improvement, enabling midstream projects to remain competitive in dynamic markets.

As the energy landscape evolves, integrating innovative technologies like digital twins, real-time monitoring, and predictive analytics will further enhance efficiency and adaptability. By embracing these practices and strategies, midstream project teams can achieve operational excellence, foster stronger stakeholder relationships, and establish leadership in a rapidly changing industry.

Disclaimer

The information provided in this post is for reference purposes only and is intended to serve as a guide to highlight key topics, considerations, and best practices. It does not constitute professional advice or a substitute for consulting regarding specific projects or circumstances. Readers are encouraged to evaluate their unique project needs and seek tailored advice where necessary. Please Contact Us to discuss your particular project.