Introduction: The Shift from Traditional to Predictive Estimating

Estimating has long been a critical function in energy project execution, guiding decision-making in cost forecasting, budgeting, and risk management. Traditionally, estimating relied on historical data, expert judgment, and deterministic models to develop cost and schedule projections. However, as projects become larger and more complex, traditional methods often struggle with accuracy, leaving room for cost overruns, schedule delays, and financial risk.

Enter predictive estimating, a game-changing approach that integrates AI, machine learning, big data analytics, and probabilistic modeling to improve estimate accuracy, enhance risk assessment, and optimize project planning. This approach leverages vast amounts of project data to provide real-time, dynamic, and adaptive estimates, reducing uncertainty and improving decision-making.

In this article, we explore:

✔️ What predictive estimating is and how it differs from traditional methods

✔️ The key technologies driving predictive estimating

✔️ How predictive models are improving estimating accuracy

✔️ Real-world applications and benefits in EPC projects

What Is Predictive Estimating?

Predictive estimating is the next evolution of cost and schedule forecasting, leveraging advanced data analytics, artificial intelligence (AI), and machine learning (ML) to generate more accurate, dynamic, and risk-adjusted estimates. It replaces traditional, static estimating methods with adaptive models that continuously refine their predictions based on real-time data.

Unlike conventional estimating, which relies on historical benchmarks, expert judgment, and deterministic calculations, predictive estimating integrates probabilistic analysis, real-time data feeds, and AI-driven insights to create a more realistic representation of project costs and schedules.

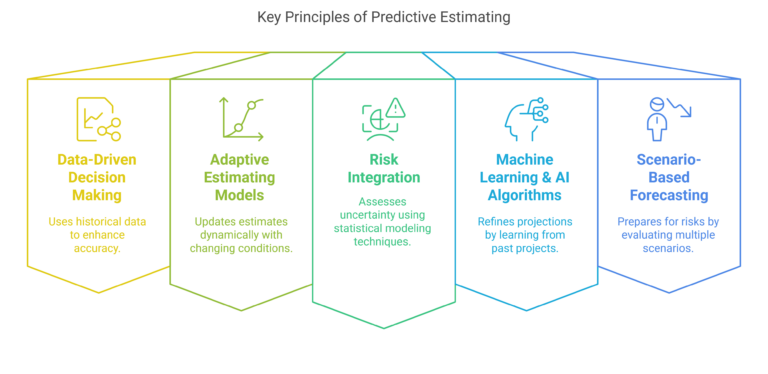

Key Principles of Predictive Estimating

- Data-Driven Decision Making: Uses historical project data, market trends, and real-time inputs to improve accuracy.

- Adaptive Estimating Models: Unlike static estimates, predictive models update dynamically as conditions change.

- Risk Integration: Incorporates statistical modeling (e.g., Monte Carlo simulations) to assess cost and schedule uncertainty.

- Machine Learning & AI Algorithms: Continuously learn from past projects to refine cost and schedule projections.

- Scenario-Based Forecasting: Evaluates multiple “what-if” scenarios to prepare for potential risks and deviations.

How Predictive Estimating Differs from Traditional Estimating

Traditional estimating methods rely on fixed assumptions, static cost databases, and a combination of expert judgment and parametric cost models. While these methods provide a starting point, they often struggle with accuracy, adaptability, and real-time adjustments.

Predictive estimating, on the other hand, constantly evolves by analyzing historical trends, supplier pricing fluctuations, and real-time market data. This results in dynamic and more reliable cost and schedule forecasts.

Comparison of Traditional vs. Predictive Estimating

Feature | Traditional Estimating | Predictive Estimating |

Data Source | Static historical databases & expert judgment | AI, machine learning, real-time project data |

Accuracy | Subject to human bias, may be outdated | Continuously refines estimates through AI algorithms |

Risk Assessment | Based on static contingency percentages | Uses Monte Carlo simulations & risk-adjusted cost models |

Adaptability | Fixed at project start | Adjusts dynamically as conditions evolve |

Speed of Updates | Manual recalculations required | Automated updates based on real-time data |

Decision Support | Relies on project team adjustments | AI-driven recommendations for cost and schedule optimization |

For example, in a large-scale EPC project, traditional estimates may assume fixed material costs and static labor rates based on last year’s data. Predictive estimating, however, uses AI-driven procurement analytics to monitor market price fluctuations, helping project teams adjust estimates before cost escalations occur.

How Predictive Estimating Works

Predictive estimating is powered by data analytics, AI, and machine learning models that analyze thousands of variables to produce probabilistic, rather than deterministic, cost estimates.

1. Data Collection & Integration

Predictive estimating aggregates multiple data sources, including:

✅ Historical project data: Past cost performance, labor productivity, and schedule deviations.

✅ Market intelligence: Real-time supplier costs, material price fluctuations, and inflation trends.

✅ Site conditions & external factors: Weather data, geopolitical risks, and regulatory changes.

✅ Live project tracking data: IoT sensors, drones, and digital twin technology for progress monitoring.

These data points are fed into AI models, allowing predictive tools to refine estimates continuously based on emerging trends and real-time changes.

2. AI-Powered Analysis & Modeling

AI and machine learning algorithms process the collected data to:

✔ Identify patterns and trends in project execution

✔ Compare cost and productivity rates across similar projects

✔ Highlight anomalies or deviations from historical benchmarks

✔ Run probabilistic simulations to model different project scenarios

For instance, if an AI model detects that labor productivity in a refinery project is 10% lower than expected, it will adjust the estimate dynamically, reflecting potential schedule and budget risks.

3. Scenario-Based Forecasting & Risk Modeling

Predictive estimating tools incorporate Monte Carlo simulations and Bayesian probability models to create multiple potential outcomes instead of relying on a single “most likely” estimate.

🔹 Example: If a predictive model calculates that steel prices could fluctuate by ±8% in the next six months, it will produce an estimate range based on probability distributions instead of a single fixed price assumption.

Instead of saying,

"The estimated project cost is $500M,"

predictive estimating provides a probability distribution like:

"There is a 75% chance the project will cost between $480M and $520M based on current market conditions."

This probabilistic approach provides better risk management and decision-making capabilities.

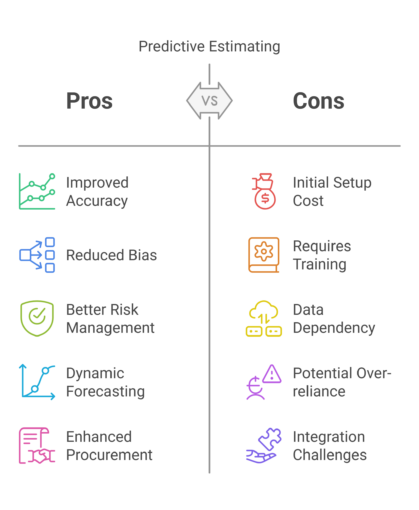

Key Advantages of Predictive Estimating

✅ Improved Accuracy & Reduced Bias

- Uses real-time data and AI learning models instead of relying solely on human judgment.

- Eliminates outdated cost assumptions by continuously refining estimates.

✅ Better Risk Management & Contingency Planning

- Identifies high-risk areas in a project before they cause cost overruns.

- Adjusts contingencies dynamically based on probability-based cost exposure.

✅ Dynamic & Adaptive Cost Forecasting

- Updates cost and schedule forecasts automatically as project conditions change.

- Enables real-time "what-if" scenario planning for proactive decision-making.

✅ Enhanced Procurement & Supply Chain Management

- Predictive analytics help in early supplier negotiations and cost-locked contracts to avoid price escalations.

- AI-driven procurement models anticipate raw material shortages and logistics delays.

🔹 Example: A major energy project used AI-driven predictive estimating to adjust its procurement strategy when early indicators showed potential price hikes in copper. By securing early bulk purchases, the project saved 12% on total material costs.

Real-World Example of Predictive Estimating in EPC Projects

Case Study: AI-Powered Cost Estimating in a Large-Scale LNG Project

A $2.5 billion LNG processing facility faced major estimating challenges due to:

✔ Fluctuating steel and pipe material costs

✔ Uncertain labor productivity rates

✔ Volatile global supply chain risks

Traditional Estimating Approach:

- Used fixed cost assumptions based on past LNG projects.

- Contingency was set at 10% across all cost categories, without detailed risk assessment.

- No real-time procurement data integration for material price updates.

Predictive Estimating Approach:

- AI-driven models monitored real-time supplier pricing trends and flagged an impending 15% increase in steel costs.

- Machine learning algorithms analyzed past LNG projects and suggested a 7% productivity drop in certain labor-intensive phases.

- Monte Carlo simulations calculated risk-adjusted contingencies specific to high-variance cost items.

Outcome:

🔹 The project adjusted its procurement timing, securing lower-priced steel before market price hikes.

🔹 AI-based labor productivity forecasts led to a reallocation of labor resources, improving efficiency.

🔹 Instead of applying a flat 10% contingency, a data-driven contingency allocation saved $80M in unnecessary reserves.

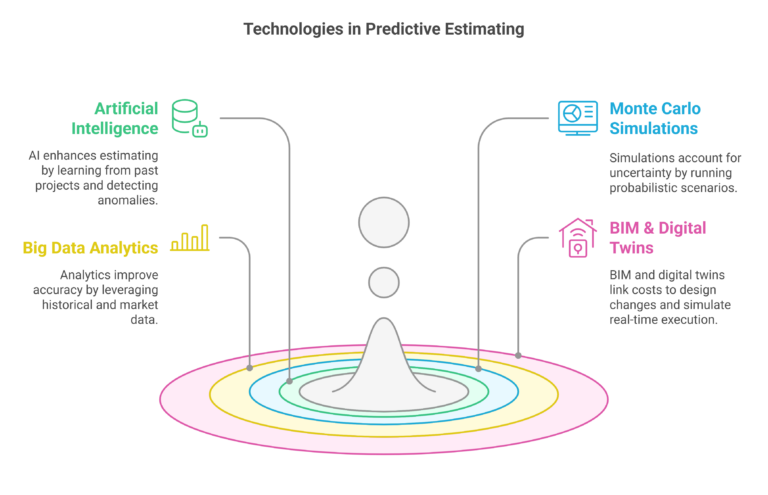

Technologies Driving Predictive Estimating

Predictive estimating is powered by several advanced technologies that enhance its accuracy and reliability:

1. Artificial Intelligence & Machine Learning

- AI-driven estimating software learns from past projects to refine future cost and schedule predictions.

- Machine learning models analyze patterns in labor productivity, material costs, and procurement trends.

- AI can detect anomalies in project estimates that may indicate under-budgeting or unrealistic schedules.

2. Monte Carlo Simulations

- Runs thousands of probabilistic scenarios to account for uncertainty in labor costs, material prices, and schedule delays.

- Generates a range of possible outcomes, rather than a single-point estimate.

3. Big Data Analytics

- Pulls data from historical projects, market trends, and supplier pricing to improve estimate accuracy.

- Identifies cost-saving opportunities through benchmarking against similar projects.

4. Building Information Modeling (BIM) & Digital Twins

- BIM-driven cost modeling improves estimate precision by linking costs directly to design changes.

- Digital twins simulate project execution in real-time, allowing for dynamic cost forecasting.

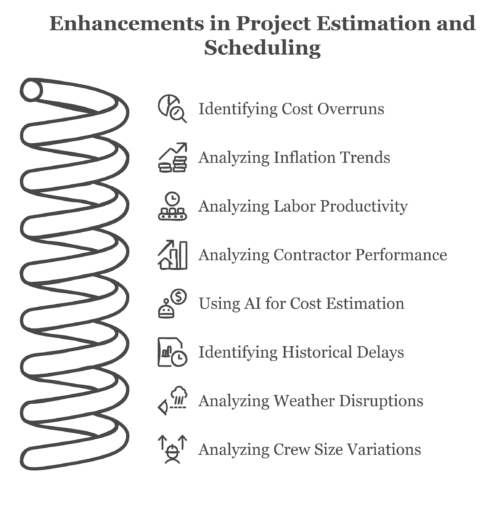

How Predictive Models Are Improving Estimating Accuracy

1. Reducing Cost Overruns

Traditional estimating methods often underestimate risks, leading to budget blowouts. Predictive models analyze:

✔ Inflation trends in material costs

✔ Labor productivity rates based on real-time conditions

✔ Contractor performance and pricing trends

🔹 Example: A major oil & gas project used AI-based cost estimation and improved estimate accuracy by 15%, reducing unforeseen budget overruns.

2. Improving Schedule Forecasting

Predictive scheduling tools analyze:

✔ Historical delays on similar projects

✔ Weather and supply chain disruptions

✔ Productivity variations based on crew size

🔹 Example: A renewable energy project used AI-powered scheduling forecasts, reducing expected delays by 20% compared to traditional CPM-based schedules.

3. Enhancing Risk Assessment

Traditional risk assessment methods assign static contingency reserves, often misjudging project risks.

- Predictive models dynamically adjust contingency levels based on real-time risk analysis.

- AI identifies high-risk project phases based on historical failure rates.

🔹 Example: A refinery project used Monte Carlo simulations to identify the probability of exceeding budget, leading to a more realistic contingency plan.

Real-World Applications of Predictive Estimating in EPC Projects

✔ Large-Scale Infrastructure Projects: AI-based estimating has helped transportation megaprojects improve cost forecasts and avoid overruns.

✔ Oil & Gas Projects: Predictive analytics have optimized drilling and processing facility budgets through real-time market analysis.

✔ Renewable Energy Projects: AI-driven scheduling has improved solar and wind farm execution timelines by analyzing weather disruptions.

✔ Industrial Manufacturing Plants: AI has enhanced procurement planning and supplier cost forecasting for large-scale plants.

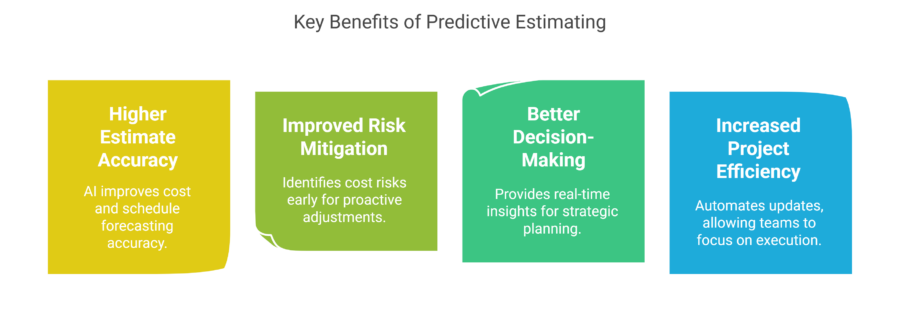

Key Benefits of Predictive Estimating

✅ Higher Estimate Accuracy

- AI and predictive analytics reduce bias in cost and schedule forecasting.

- Probabilistic models provide realistic cost ranges, not just single-point estimates.

✅ Improved Risk Mitigation

- Early identification of cost risks allows for proactive budget adjustments.

- Helps avoid unexpected delays and cash flow disruptions.

✅ Better Decision-Making

- Provides real-time insights for finance teams and project managers.

- Enhances strategic planning for capital allocation.

✅ Increased Project Efficiency

- AI automates cost updates, procurement forecasts, and risk tracking.

- Teams spend less time manually adjusting estimates and more time executing projects.

Conclusion: The Future of Predictive Estimating

Predictive estimating is not just an enhancement of traditional methods, it is a fundamental shift in how projects are planned and executed. By leveraging AI, machine learning, and real-time data, EPC firms can improve cost control, mitigate risks, and optimize project execution.

As more companies adopt predictive estimating, we will see:

🔹 Deeper AI integration with project management platforms.

🔹 Automated real-time cost updates based on live market trends.

🔹 AI-driven contract negotiations using supplier cost predictions.

For companies looking to stay competitive in the evolving industrial project landscape, embracing predictive estimating is not optional, it’s essential.

Disclaimer

The information provided in this post is for reference purposes only and is intended to serve as a guide to highlight key topics, considerations, and best practices. It does not constitute professional advice or a substitute for consulting regarding specific projects or circumstances. Readers are encouraged to evaluate their unique project needs and seek tailored advice where necessary. Please Contact Us to discuss your particular project.