The success of energy projects often hinges on selecting the right contract type. Contracts define how financial risks, responsibilities, and rewards are shared between stakeholders, making them a cornerstone of effective project management. Whether it’s a Lump Sum contract for predictable scopes or a Time and Materials (T&M) approach for flexible projects, choosing the best fit can significantly influence cost control, risk allocation, and execution efficiency.

This guide explores the key contract types used in industrial projects, including Lump Sum, T&M, Cost Plus, and Guaranteed Maximum Price (GMP). By understanding the strengths, weaknesses, and ideal applications of each, stakeholders can align contract selection with project goals to ensure streamlined execution, cost certainty, and risk mitigation. Armed with these insights, project teams can craft contracts that pave the way for success.

Note: This article references projects execution types. Please see an overview here.

Overall Summary Table of Contract Types and Execution Models

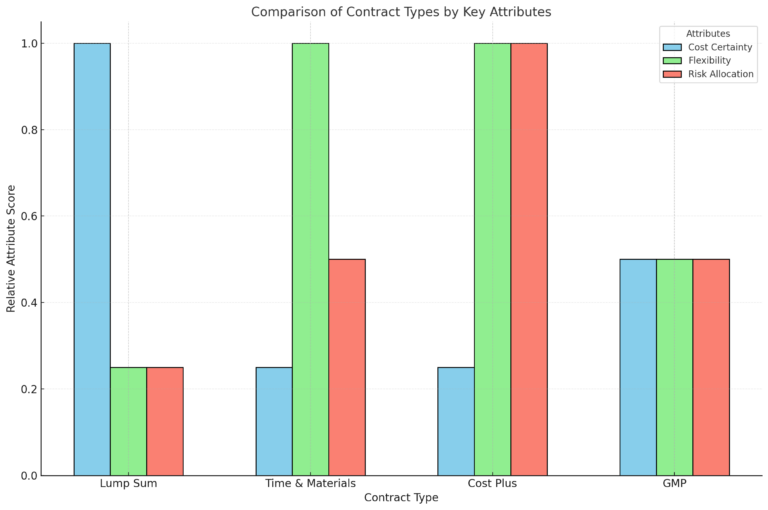

Contract Type | Cost Certainty | Flexibility | Risk Allocation | Common Execution Models |

Lump Sum | High | Low | Contractor | |

Time & Materials | Low | High | Shared | |

Cost Plus | Low | High | Client | IPD, CMAR |

GMP | Moderate-High | Moderate | Shared | CMAR, IPD |

- Cost Certainty: Higher certainty is represented by higher scores (e.g., "High" = 1.0).

- Flexibility: Higher flexibility corresponds to higher scores.

- Risk Allocation: Reflects whether risk is shared, placed on the contractor "Low", or the client "High".

Lump Sum Contracts

Overview:

A Lump Sum contract, also known as a fixed-price contract, involves the contractor agreeing to complete a project for a predetermined, fixed price. This type of contract places the financial risk largely on the contractor, as they are responsible for delivering the agreed-upon scope within the set budget.

Pros:

- Cost Certainty: The total cost is fixed, providing predictability for the client.

- Incentivizes Efficiency: Contractors have a strong incentive to manage costs and adhere to schedules.

- Simplified Management: The client’s administrative burden is reduced.

Cons:

- Limited Flexibility: Changes to the project scope can be costly and time-consuming to negotiate.

- Potential for Reduced Quality: Contractors may cut corners to maintain profitability.

- High Risk for Contractors: Unexpected costs are the contractor’s responsibility.

Best For:

Projects with a well-defined scope, minimal anticipated changes, and clear deliverables, such as straightforward infrastructure builds.

Common Execution Models:

- Design-Bid-Build

- Engineering, Procurement, and Construction (EPC)

Example:

Construction of a natural gas processing facility where the scope and design are fully defined upfront, ensuring fixed pricing and minimal changes during execution.

Time and Materials (T&M) Contracts

Overview:

In a T&M contract, the client pays the contractor based on the time spent and materials used. This arrangement provides flexibility to adapt the scope as the project progresses.

Pros:

- Flexibility: Accommodates changes to scope without renegotiating the entire contract.

- Transparency: Clients have visibility into actual costs and progress.

- Encourages Collaboration: Ideal for projects requiring close client-contractor coordination.

Cons:

- Cost Uncertainty: Total project costs can be difficult to predict.

- Risk for Clients: Poorly managed projects can lead to inefficiencies and higher expenses.

- Requires Oversight: Clients must actively monitor progress to ensure accountability.

Best For:

Projects with evolving scopes, uncertain requirements, or early-stage designs, such as R&D facilities or custom manufacturing systems.

Common Execution Models:

Example:

Development of a pilot hydrogen production plant where the process and equipment need iterative adjustments based on real-time results.

Cost Plus Contracts

Overview:

Cost Plus contracts reimburse the contractor for actual costs incurred, plus a predetermined fee or percentage for profit. Variations of this contract include Cost Plus Fixed Fee (CPFF) and Cost Plus Incentive Fee (CPIF).

Pros:

- Transparent Costs: Clients see detailed cost breakdowns.

- Encourages Quality: Contractors are incentivized to deliver high-quality work without the constraint of fixed budgets.

- Flexibility for Complex Projects: Allows adjustments to scope without penalizing contractors.

Cons:

- Cost Risk for Clients: Without strict controls, costs can escalate.

- Administrative Burden: Detailed tracking of expenses is required.

- Reduced Incentive for Efficiency: Contractors may have less motivation to minimize costs.

Best For:

Projects with high uncertainty or complexity, where scope or conditions are likely to evolve, such as large industrial plant upgrades.

Common Execution Models:

- Integrated Project Delivery (IPD)

- Construction Management at Risk (CMAR)

Example:

Retrofitting an aging offshore oil platform to meet new environmental regulations, where unexpected issues may arise during execution.

Guaranteed Maximum Price (GMP) Contracts

Overview:

GMP contracts set a ceiling price for the project. The contractor is compensated for actual costs up to the maximum price and may share in savings if costs are below the ceiling.

Pros:

- Cost Control: Limits the client’s financial exposure.

- Shared Incentives: Encourages contractors to manage costs effectively.

- Transparency: Clients have visibility into project costs.

Cons:

- Higher Initial Pricing: Contractors may include contingencies to cover risks.

- Complex Negotiations: Establishing a fair maximum price requires detailed planning.

- Limited Flexibility: Changes to the scope may require renegotiation.

Best For:

Projects requiring a balance of cost certainty and flexibility, such as public-private partnerships or large-scale facility construction.

Common Execution Models:

- Construction Management at Risk (CMAR)

- Integrated Project Delivery (IPD)

Example:

Construction of a renewable energy wind farm where the client wants cost certainty but also incentivizes cost savings during execution.

Decision-Making Flowchart

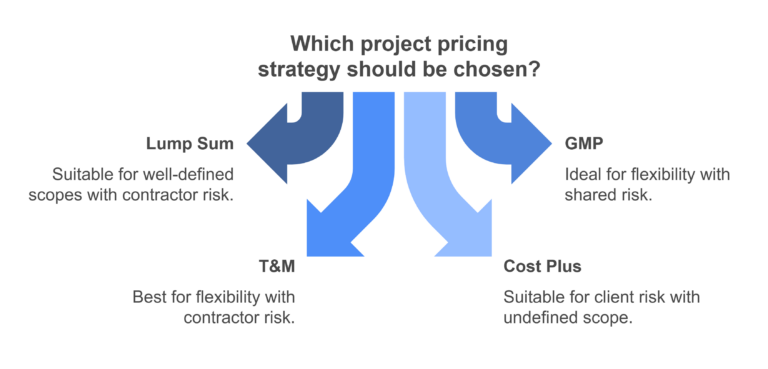

Step 1: Is the project scope well-defined?

- Yes: Consider Lump Sum or GMP.

- No: Move to Step 2.

Step 2: Is flexibility a priority?

- Yes: Consider T&M or Cost Plus.

- No: Consider GMP with clearly defined constraints.

Step 3: What is the desired risk allocation?

- Contractor: Lump Sum.

- Shared: GMP or T&M.

- Client: Cost Plus.

Risk Mitigation Strategies

- For Lump Sum Contracts: Conduct thorough planning and design reviews to minimize scope changes.

- For T&M Contracts: Implement robust monitoring and reporting systems to ensure efficiency.

- For Cost Plus Contracts: Set clear spending limits and establish incentive mechanisms.

- For GMP Contracts: Perform detailed pre-construction planning to accurately set the ceiling price.

Emerging Contract Models

- Performance-Based Contracts: Payments are tied to specific performance outcomes rather than project milestones.

- Alliance Contracts: Collaborative agreements where all parties share risks and rewards equally, fostering innovation and efficiency.

Common Challenges and Solutions

Challenge | Solution |

Scope changes in Lump Sum | Conduct detailed planning and include contingency. |

Cost overruns in T&M | Regular audits and contractor performance reviews. |

Tracking in Cost Plus | Utilize project management software for transparency. |

Ceiling disputes in GMP | Engage in open-book pricing negotiations. |

Checklist for Selecting a Contract Type

Scope Definition:

- Is the project scope clear and well-defined?

- Yes: Lump Sum or GMP may be appropriate.

- No: Consider T&M or Cost Plus.

Risk Tolerance:

- Does the client prefer to share or minimize risk?

- Minimize risk: Lump Sum or GMP.

- Share risk: T&M or Cost Plus.

Cost Control:

- Is cost certainty a priority?

- High priority: Lump Sum or GMP.

- Less critical: T&M or Cost Plus.

Project Complexity:

- Is the project technically or logistically complex?

- High complexity: T&M or Cost Plus.

- Low complexity: Lump Sum or GMP.

Flexibility Needs:

- Does the project require adaptability during execution?

- Yes: T&M or Cost Plus.

- No: Lump Sum or GMP.

Conclusion

Understanding the strengths and weaknesses of each contract type is essential for aligning project goals with execution strategies. Whether prioritizing cost control, flexibility, or risk management, selecting the right contract type lays the foundation for successful project delivery. By tailoring contract terms to project-specific requirements, stakeholders can navigate challenges and achieve optimal outcomes.

Disclaimer

The information provided in this post is for reference purposes only and is intended to serve as a guide to highlight key topics, considerations, and best practices. It does not constitute professional advice or a substitute for consulting regarding specific projects or circumstances. Readers are encouraged to evaluate their unique project needs and seek tailored advice where necessary. Please Contact Us to discuss your particular project.