Hydrogen is emerging as a pivotal player in the global energy transition, offering unparalleled potential to decarbonize industries, enhance energy storage, and drive innovation across multiple sectors. Recognized for its versatility, hydrogen can serve as a clean energy carrier, fuel industrial processes, and support long-term energy storage solutions. However, while hydrogen presents transformative opportunities, it also faces significant challenges related to production costs, infrastructure development, and energy efficiency.

This guide provides critical insights into the role of hydrogen in the clean energy transition, highlighting key projects, exploring its diverse applications, and addressing the pitfalls that must be navigated to unlock its full potential. By understanding both the opportunities and challenges, stakeholders can strategically position hydrogen within a diversified and sustainable energy system.

My Opinion: In my opinion, hydrogen will not overtake traditional oil and gas in our lifetime but will act as a supplement where it is economically viable. At the end of the day, economics must justify its production and use. While many hydrogen projects are currently supported by government subsidies which I agree are essential for the development and advancement of the technology the cost of hydrogen must eventually align with its value to achieve widespread adoption.

We are already seeing major oil companies pulling back or significantly reducing their investments in the green energy sector, opting instead for more efficient and environmentally friendly approaches to historical markets. For example, traditional gas generation systems equipped with post-combustion carbon capture technology are often more efficient and cost-effective than hydrogen-based generation.

Hydrogen certainly has a role to play in the energy industry, particularly in niche applications and as part of a diversified energy system. However, it is not the sole answer to the challenges of decarbonization and energy sustainability.

Companion Content: See Understanding the Hydrogen Value Chain for additional information on the key components of the hydrogen value chain, exploring its production methods, storage solutions, transportation systems, and end-use applications.

Examples of Hydrogen Energy Projects

Hydrogen energy projects span a wide range of applications, each tailored to meet specific energy needs and regional priorities. These projects demonstrate the versatility of hydrogen as a clean energy source and its potential to decarbonize various sectors. Below are the key types of hydrogen energy projects and their roles in the energy transition:

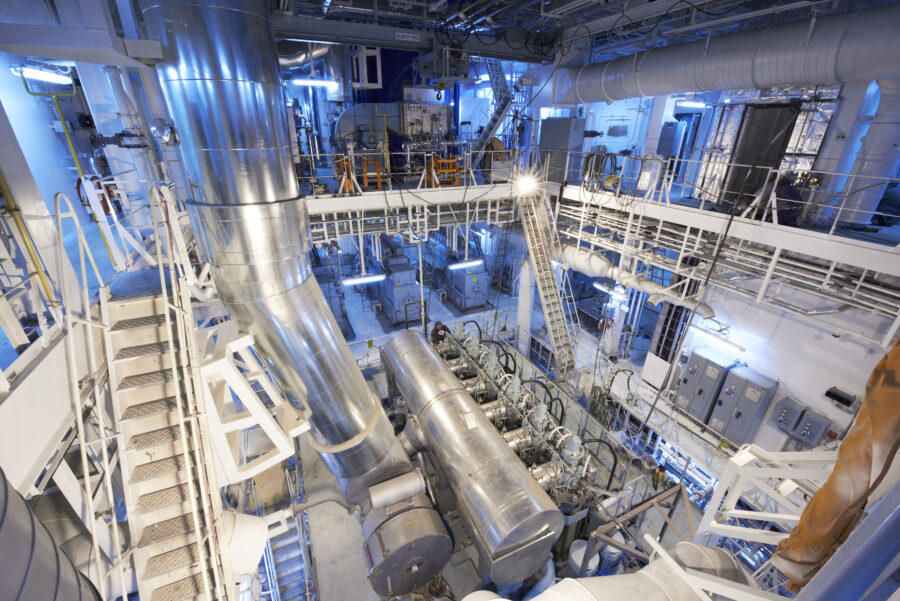

Large-Scale Green Hydrogen Production Facilities

These projects focus on producing green hydrogen using renewable energy sources such as solar and wind. Electrolysis plants convert water into hydrogen and oxygen, creating a clean and sustainable energy carrier. Large-scale facilities are designed to meet growing domestic demand or to export hydrogen to international markets.

- Primary Role: Decarbonizing industrial processes and heavy transport sectors.

- Example Use Case: A solar-powered hydrogen plant producing fuel for long-haul trucks and maritime shipping.

Hydrogen Energy Storage Systems

Hydrogen storage projects address the intermittency of renewable energy by converting surplus electricity into hydrogen. The stored hydrogen can be used later to generate electricity, balance grid demand, or support seasonal energy storage needs.

- Primary Role: Enhancing grid stability and supporting renewable energy integration.

- Example Use Case: Underground hydrogen storage in salt caverns to provide electricity during high-demand periods.

Industrial Decarbonization Initiatives

These projects replace traditional fossil fuels with hydrogen in energy-intensive industries such as steelmaking, cement production, and chemicals manufacturing. Hydrogen’s ability to provide high-temperature heat and act as a feedstock makes it a critical tool for reducing emissions in these sectors.

- Primary Role: Lowering carbon emissions from hard-to-abate industrial processes.

- Example Use Case: Hydrogen replacing coal in steel production through direct reduction methods.

Hydrogen-Powered Transportation Projects

Hydrogen is increasingly being used in transportation, from fuel cell vehicles to trains and ships. Hydrogen refueling stations are being established to support the adoption of hydrogen-powered vehicles, especially in sectors like freight, transit, and aviation.

- Primary Role: Decarbonizing transport and supporting the shift away from fossil fuels.

- Example Use Case: A hydrogen-powered bus fleet with supporting refueling infrastructure in urban areas.

Hydrogen Blending in Gas Networks

Hydrogen blending involves mixing hydrogen with natural gas in existing pipelines to reduce the carbon intensity of delivered gas. These projects are designed to decarbonize residential heating and industrial applications without requiring significant infrastructure changes.

- Primary Role: Gradual decarbonization of heating and energy delivery systems.

- Example Use Case: Adding 20% hydrogen to existing natural gas pipelines to lower emissions from home heating.

Regional Hydrogen Hubs

Hydrogen hubs integrate production, storage, and distribution infrastructure to create localized hydrogen ecosystems. These hubs often serve multiple applications, such as powering local industries, fueling transportation, and supplying residential or commercial energy needs.

- Primary Role: Creating self-sufficient, regional hydrogen economies.

- Example Use Case: A hydrogen hub supplying nearby industrial plants and public transportation systems.

Opportunities in Hydrogen Energy Projects

Decarbonization Potential

Hydrogen, particularly green hydrogen produced through electrolysis using renewable energy, has the potential to significantly reduce greenhouse gas emissions. As a clean-burning fuel, hydrogen emits only water as a byproduct. This makes it an attractive option for sectors that are difficult to decarbonize, such as steel production, shipping, aviation, and heavy transport.

Globally, initiatives like the EU Green Deal and national hydrogen strategies in countries like Japan, Australia, and the United States are creating strong policy frameworks to integrate hydrogen into the energy mix. Hydrogen can replace fossil fuels in industrial heat processes, provide fuel for hydrogen-powered vehicles, and serve as a clean feedstock for chemicals such as ammonia and methanol.

Expanded Insight:

- Hydrogen could cut emissions from the steel industry by up to 90%, replacing coal-based blast furnaces with hydrogen-based direct reduction processes.

- Hydrogen fuel cell vehicles offer two-to-three times the range of battery electric vehicles (BEVs) and can be refueled in minutes, making them ideal for long-haul trucking and public transit.

Energy Storage and Grid Stability

One of hydrogen’s most transformative roles lies in energy storage and grid stabilization. Renewable energy sources like wind and solar are intermittent, generating electricity only when the sun shines or the wind blows. Hydrogen bridges this gap by converting surplus electricity into hydrogen via electrolysis, which can then be stored and used during periods of low renewable output.

Hydrogen’s scalability makes it ideal for seasonal storage, addressing the mismatch between renewable generation and consumption. For example, surplus energy produced in summer can be stored as hydrogen and utilized during winter months.

Expanded Insight:

- Hydrogen has a storage capacity of up to 10 times more energy per unit volume than lithium-ion batteries, making it a viable solution for large-scale grid storage.

- Hydrogen storage supports the integration of distributed energy resources (DERs), enhancing grid resilience and enabling microgrid solutions.

Industrial and Economic Development

Hydrogen energy projects have the potential to catalyze industrial innovation and economic growth. Investments in hydrogen production, distribution, and utilization infrastructure can create new jobs, drive regional development, and position nations as leaders in the global hydrogen economy.

Countries rich in renewable energy resources, such as solar or wind, can produce green hydrogen for export, opening up new international markets. Additionally, the construction and operation of hydrogen facilities stimulate local economies, generating employment opportunities in engineering, manufacturing, and logistics.

Expanded Insight:

- According to the Hydrogen Council, the global hydrogen economy could create 30 million jobs and contribute over $2.5 trillion annually to GDP by 2050.

- Hydrogen export hubs in Australia and the Middle East are expected to drive significant foreign investment and foster regional partnerships.

Policy and Financial Support

Governments and international organizations are increasingly prioritizing hydrogen in their climate strategies. Financial incentives such as grants, subsidies, tax credits, and carbon pricing mechanisms are accelerating the deployment of hydrogen technologies. For instance, the U.S. Inflation Reduction Act includes provisions for clean hydrogen production tax credits, while Europe’s Hydrogen Strategy targets the installation of 40 GW of electrolyzer capacity by 2030.

Public-private partnerships are also playing a crucial role in fostering hydrogen innovation, reducing risks, and encouraging investment in infrastructure and R&D.

Expanded Insight:

- Germany has allocated €9 billion to develop a green hydrogen economy, focusing on domestic production and international partnerships.

- The Clean Hydrogen Partnership in Europe has launched over 300 projects, combining public and private funding to bridge supply chain gaps.

Versatility in Applications

Hydrogen’s versatility makes it applicable across various industries and energy systems. Its applications include:

- Transportation: Hydrogen fuel cells are powering buses, trucks, trains, and even aircraft, offering a clean alternative to traditional fuels.

- Industrial Heat: Hydrogen can replace natural gas in high-temperature industrial processes, such as glassmaking and cement production.

- Power Generation: Hydrogen turbines and combined heat and power (CHP) systems can deliver reliable, emission-free electricity.

- Chemicals and Fertilizers: Hydrogen is a key feedstock for ammonia and methanol production, which are essential for fertilizers and petrochemicals.

Expanded Insight:

- Companies like Airbus are developing hydrogen-powered planes, aiming for commercialization by 2035, which could transform aviation’s carbon footprint.

- Hydrogen trains are being deployed in Europe and Asia, replacing diesel-powered locomotives on non-electrified tracks.

Challenges in Hydrogen Energy Projects

High Production Costs

One of the most significant challenges in hydrogen adoption is the high cost of production, especially for green hydrogen. Electrolysis, the process of splitting water into hydrogen and oxygen, requires substantial amounts of electricity. When powered by renewable energy, the cost of hydrogen production becomes closely tied to renewable electricity prices.

Gray hydrogen, produced from natural gas, is significantly cheaper but emits carbon dioxide, negating its environmental benefits. Until green hydrogen production costs drop, its adoption will remain limited to niche applications.

Expanded Insight:

- The cost of producing green hydrogen ranges from $4–$6 per kilogram, compared to $1–$2 per kilogram for gray hydrogen.

- Innovations like solid oxide electrolyzers and economies of scale are expected to reduce costs by up to 50% over the next decade.

Infrastructure Challenges

Hydrogen infrastructure, including production facilities, pipelines, storage systems, and refueling stations, is underdeveloped. Hydrogen’s low density necessitates compression or liquefaction for transport, both of which are capital-intensive. Additionally, retrofitting existing natural gas pipelines for hydrogen transport requires significant upgrades to prevent embrittlement.

The lack of infrastructure creates a chicken-and-egg problem: developers hesitate to invest in infrastructure without clear demand, while demand remains limited due to insufficient infrastructure.

Expanded Insight:

- Currently, there are fewer than 1,000 hydrogen refueling stations worldwide, compared to hundreds of thousands for gasoline and EV charging.

- Building a dedicated hydrogen pipeline network could cost $200 billion globally by 2050, according to IEA estimates.

Energy Efficiency Losses

Hydrogen’s energy conversion processes involve significant inefficiencies. Electrolysis to produce hydrogen, compression or liquefaction for storage, and conversion back to electricity in fuel cells all result in energy losses. These inefficiencies make hydrogen less attractive for applications where direct electrification is feasible.

Expanded Insight:

The energy required to produce hydrogen compared to the energy it delivers is a critical factor in its role as an energy carrier. Here’s a breakdown of the energy efficiency challenges associated with hydrogen production and utilization:

Energy Required to Produce Hydrogen

The production of hydrogen, especially green hydrogen, involves significant energy losses:

Green Hydrogen (Electrolysis)

- Process: Water is split into hydrogen and oxygen using electricity in an electrolyzer.

- Efficiency: Electrolysis systems are typically 60–70% efficient, meaning that 30–40% of the energy used is lost as heat during the process.

- Example: For every 100 kWh of electricity used, only 60–70 kWh of hydrogen energy is produced.

Gray and Blue Hydrogen (Natural Gas Reforming)

- Process: Hydrogen is produced from natural gas through steam methane reforming (SMR), with or without carbon capture.

- Efficiency: SMR is about 65–75% efficient, with energy losses in the reforming process and carbon capture steps.

- Example: For every 100 units of energy in natural gas, 65–75 units are captured as hydrogen.

Energy Delivered by Hydrogen

Hydrogen’s end-use efficiency depends on the application:

Fuel Cells

- Process: Hydrogen is converted back into electricity in a fuel cell.

- Efficiency: Fuel cells are about 50–60% efficient, meaning 40–50% of the energy is lost during the conversion process.

- Combined Efficiency: When accounting for both electrolysis and fuel cell conversion, the overall energy efficiency of green hydrogen can drop to 30–40%.

Combustion Engines or Power Plants

- Process: Hydrogen is burned in turbines or engines to produce electricity or heat.

- Efficiency: Combustion-based systems are typically 30–40% efficient, which is comparable to conventional power plants but lower than fuel cells.

Energy Efficiency Comparison: Hydrogen vs. Other Systems

When comparing hydrogen to other energy carriers or storage solutions, the efficiency gap becomes evident:

System | Efficiency | Energy Losses |

Hydrogen (Electrolysis + Fuel Cell) | 30–40% | Significant losses in both production and utilization |

Batteries | 80–90% (round-trip) | Minimal losses in charging and discharging |

Natural Gas (Direct Combustion) | 50–60% | Moderate losses during combustion |

Practical Implications

Hydrogen’s low round-trip efficiency compared to batteries or direct natural gas use means it is less suited for applications where efficiency is paramount. However, it has unique advantages:

- Long-Term Storage: Unlike batteries, hydrogen can store energy for months without degradation, making it ideal for seasonal energy storage.

- Decarbonization of Hard-to-Abate Sectors: Hydrogen excels in industries where electrification or natural gas cannot meet high energy demands (e.g., steelmaking, aviation).

- Producing, storing, and using hydrogen can result in 40–50% energy losses, compared to 15% for lithium-ion batteries in energy storage applications.

- Innovations like high-efficiency electrolyzers and hybrid energy systems aim to address these challenges.

Safety Concerns

Hydrogen’s flammability and low ignition energy make safety a critical consideration in hydrogen energy projects. Specialized storage, transport, and handling systems are required to prevent leaks and mitigate explosion risks. Public perception of hydrogen safety can also be a barrier to adoption, emphasizing the need for education and transparent safety protocols.

Expanded Insight:

- Projects like the HySafe initiative are developing international standards to address hydrogen safety risks.

- Hydrogen sensors and automatic shutdown systems are becoming standard in industrial hydrogen installations.

Market and Policy Uncertainty

Hydrogen’s future depends heavily on consistent policy support and clear market signals. While some regions, such as the EU and Japan, have robust hydrogen strategies, others lag behind, creating fragmented demand and supply chains. This inconsistency makes long-term investment planning challenging.

Expanded Insight:

- Policy-driven subsidies for hydrogen can fluctuate based on political priorities, creating uncertainty for developers.

- Harmonized global standards for hydrogen production and trade are needed to create a stable market.

Conclusion

Hydrogen has emerged as a pivotal element in the global energy transition, offering a pathway to decarbonize industries, enhance energy storage, and support renewable energy integration. However, it is not a singular solution but rather a complementary tool in a diversified energy system. While hydrogen excels in niche applications ,such as heavy industry, long-haul transportation, and seasonal energy storage, it faces formidable challenges that prevent it from replacing traditional oil and gas entirely.

Economic viability remains a key hurdle. Green hydrogen, produced through electrolysis powered by renewable energy, is currently more expensive than fossil fuel alternatives like natural gas or gray hydrogen. Even with subsidies and government incentives, its widespread adoption will depend on achieving cost reductions through technological advancements and scaling up production. At the same time, infrastructure development lags behind, with limited pipelines, refueling stations, and storage facilities, requiring significant investment to meet future demand.

Energy efficiency is another critical limitation. Hydrogen’s production, storage, and conversion processes involve substantial energy losses compared to more direct energy solutions like batteries or natural gas combustion. These inefficiencies make hydrogen less competitive in applications where cost and efficiency are paramount. Additionally, safety concerns related to its flammability and handling requirements underscore the need for robust safety protocols and public education to foster trust and acceptance.

Despite these challenges, hydrogen’s role in decarbonizing hard-to-abate sectors is irreplaceable. Its ability to provide high-temperature heat for industrial processes, fuel for long-haul transport, and large-scale energy storage makes it indispensable in areas where electrification or other solutions fall short. Furthermore, hydrogen’s capacity to store renewable energy over long periods positions it as a critical tool for addressing the intermittency of wind and solar power.

For hydrogen to achieve its full potential, stakeholders must address cost, infrastructure, and efficiency barriers through continued innovation, collaboration, and investment. Policy alignment at the global and regional levels will also play a crucial role in creating a stable and predictable market for hydrogen technologies. By focusing on its strengths and strategically integrating it into the energy landscape, hydrogen can serve as a powerful supplement to traditional energy sources, driving the world closer to a sustainable and decarbonized future.

Stakeholders who navigate these challenges while capitalizing on hydrogen’s opportunities stand to lead the charge in building a cleaner, more sustainable energy future.

Appendix

Hydrogen Production Methods

Color | Production Method | Feedstock | Carbon Emissions | Cost ($/kg) |

Gray Hydrogen | Steam Methane Reforming (SMR) | Natural Gas | High | $1–2 |

Natural Gas | Moderate (CO₂ captured) | $2–3 | ||

Green Hydrogen | Electrolysis (Renewable Electricity) | Water + Renewable Energy | Zero | $3–6 |

Turquoise Hydrogen | Methane Pyrolysis | Natural Gas | Low (Solid Carbon Byproduct) | $2–4 |

Pink Hydrogen | Electrolysis (Nuclear Electricity) | Water + Nuclear Energy | Zero | $3–5 |

Hydrogen Transportation Methods and Costs

Method | Cost | Best Use | Key Challenge |

Pipelines | $1–2 | Large volumes, short distances | Retrofitting pipelines for H₂ handling |

Trucks/Rail | $3–6 | Moderate distances | Limited payload capacity |

Shipping (Ammonia) | $5–7 | Long distances, export | Energy loss during ammonia conversion |

Disclaimer

The information provided in this post is for reference purposes only and is intended to serve as a guide to highlight key topics, considerations, and best practices. It does not constitute professional advice or a substitute for consulting regarding specific projects or circumstances. Readers are encouraged to evaluate their unique project needs and seek tailored advice where necessary. Please Contact Us to discuss your particular project.

Great paper. How do you see gold hydrogen from traditional drilling production playing a role? Ammonia has a ton of upside for growth. Is the EU going to be looking at the emission footprint similar to LNG?