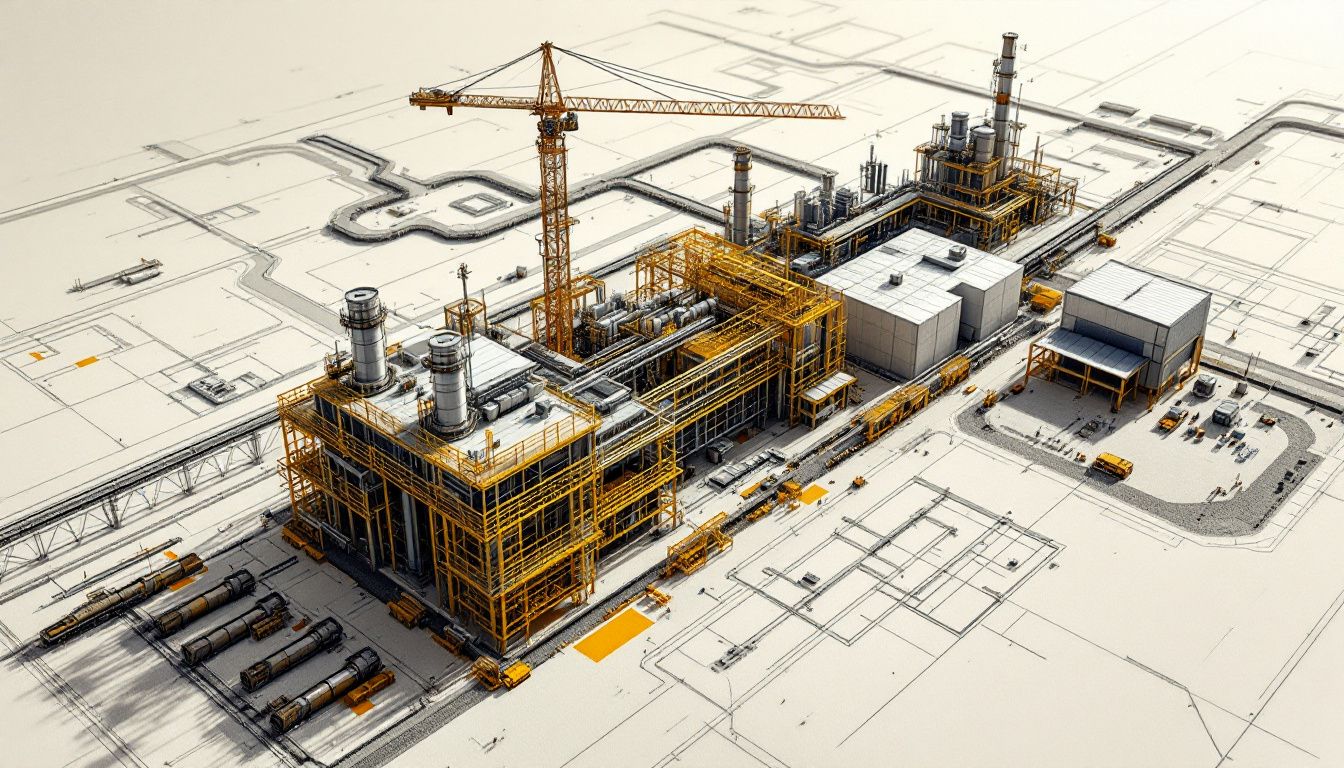

Constructability is a critical methodology in energy project development, encompassing the integration of construction expertise into the planning, design, and execution phases of a project. By incorporating constructability principles across all phases, from FEL-1 (Front-End Loading Phase 1) through detailed design, organizations can achieve optimized schedules, cost reductions, enhanced safety, and improved quality. This article outlines the role of constructability in each project phase and highlights best practices for seamless integration.

What is Constructability?

Constructability, at its core, refers to the practice of optimizing construction knowledge and experience throughout the entire lifecycle of a project. This includes early-phase planning, detailed design, procurement, and execution. Constructability ensures that designs are practical, cost-effective, safe, and efficient for construction while meeting all project requirements.

Constructability involves collaboration among all stakeholders, including engineers, designers, construction professionals, and clients. By engaging these stakeholders early in the project, constructability principles can be embedded into the design to minimize delays, reduce rework, and align construction methods with design intent.

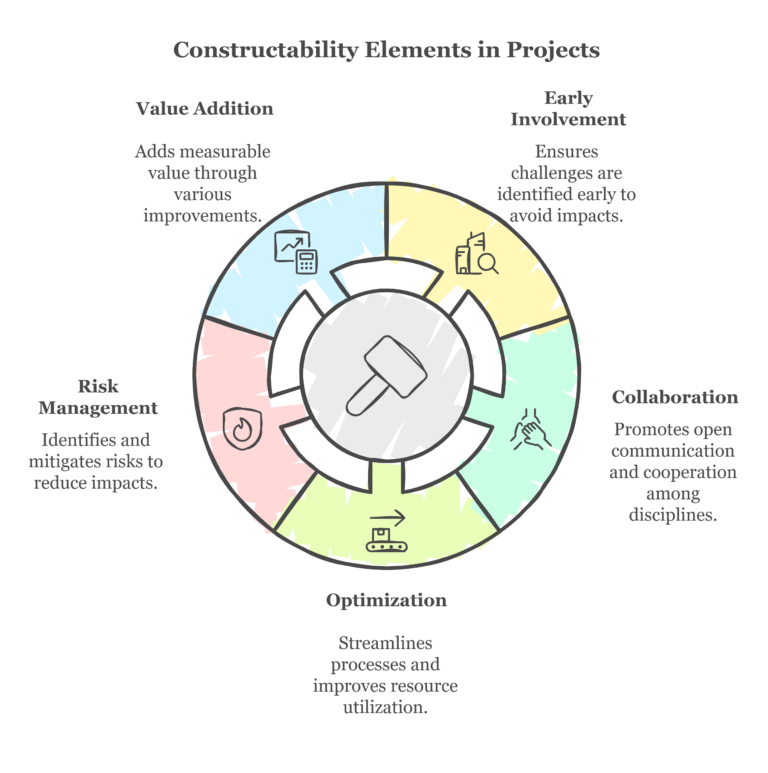

Key Elements of Constructability:

- Early Involvement: Engaging construction expertise during conceptual and early design phases ensures that potential challenges are identified and mitigated before they impact cost or schedule.

- Collaboration: Effective constructability relies on open communication and cooperation between disciplines, including engineering, procurement, construction, and commissioning.

- Optimization: The aim is to streamline processes, improve resource utilization, and develop innovative solutions to enhance project outcomes.

- Risk Management: Constructability identifies risks early and implements mitigation strategies to reduce their impact on safety, quality, and cost.

- Value Addition: Every constructability initiative should add measurable value, whether through cost savings, improved safety, or accelerated schedules.

Constructability Across Project Phases

FEL-1: Feasibility Phase

The FEL-1 phase establishes the foundation of the project, focusing on feasibility and strategic alignment. Constructability efforts during this phase concentrate on:

- Conceptual Input: Construction teams provide early input on site selection, logistics, and high-level execution strategies.

- Preliminary Risk Identification: High-level risks are identified, including site access, regulatory requirements, and labor availability.

- Execution Strategies: Feasibility assessments consider modularization, prefabrication, and advanced work packaging (AWP) opportunities.

Key Deliverables:

- Initial site evaluation reports.

- Conceptual construction execution plans.

- High-level risk assessments.

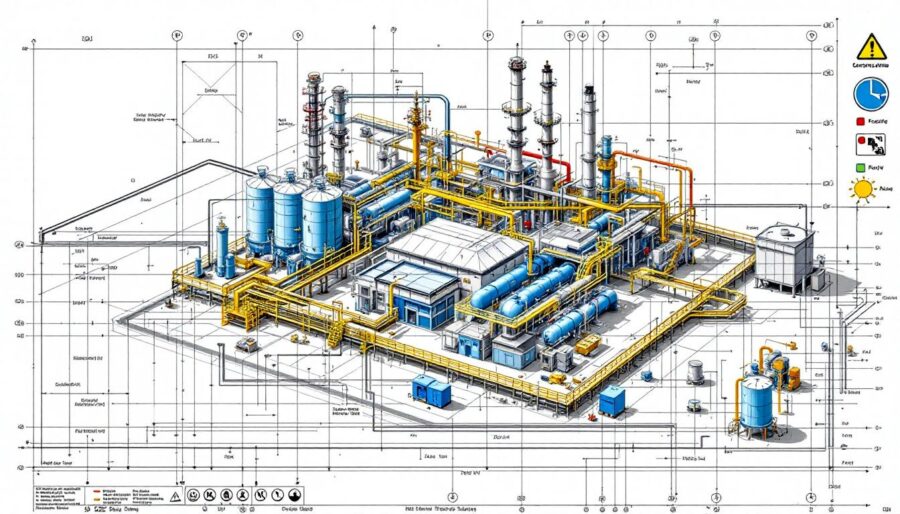

FEL-2: Concept Development Phase

In FEL-2, the project scope is refined, and constructability principles are further embedded to support project definition. Key activities include:

- Site Layout Optimization: Collaboration between construction and engineering teams ensures optimal plot plans and equipment layouts.

- Preliminary Schedule Development: Construction teams provide input on high-level schedules, identifying critical paths and potential bottlenecks.

- Regulatory Feasibility: Early reviews focus on meeting regulatory requirements to streamline future approvals.

Key Deliverables:

- Site layout and logistics studies.

- Preliminary construction execution plans.

- Initial cost and schedule estimates.

FEL-3: Front-End Engineering Design (FEED) Phase

FEL-3 solidifies the project’s design and execution strategy, making it a crucial stage for detailed constructability integration. During this phase:

- Detailed Plot Plan Reviews: Construction teams collaborate on detailed plot plan development to optimize construction workflows and reduce rework.

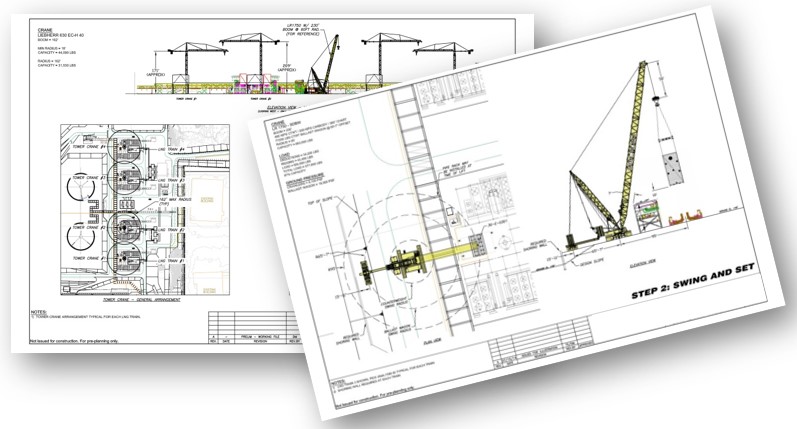

- Heavy Lift and Logistics Planning: Plans for transporting and erecting large equipment are finalized to avoid late-stage issues.

- Constructability Workshops: Collaborative workshops ensure construction input is integrated into design deliverables.

Key Deliverables:

- Detailed construction execution plans.

- Heavy lift and modularization strategies.

- Constructability workshop outcomes and action plans.

Detailed Design Phase

The detailed design phase translates FEL-3 concepts into actionable designs, with a heavy focus on constructability. Key activities include:

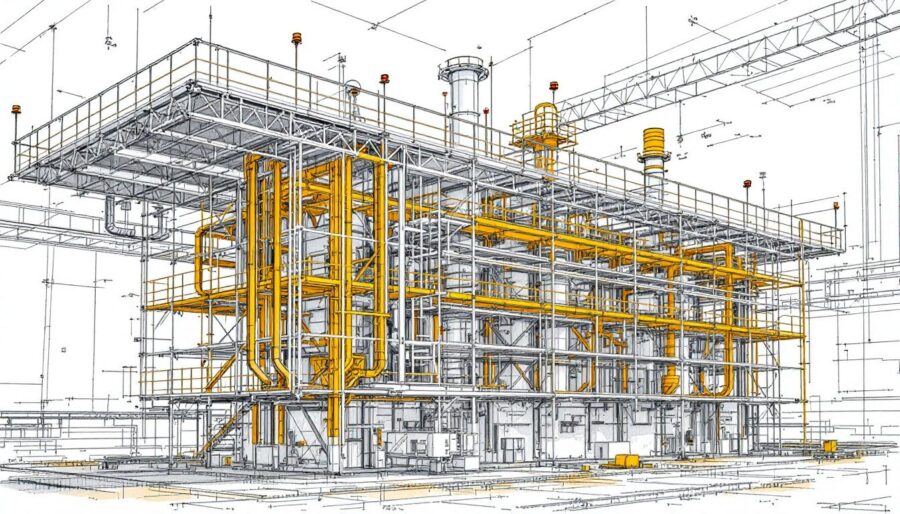

- 3D Model Reviews: Weekly model walks and interdisciplinary reviews address construction access, safety, and field welding locations.

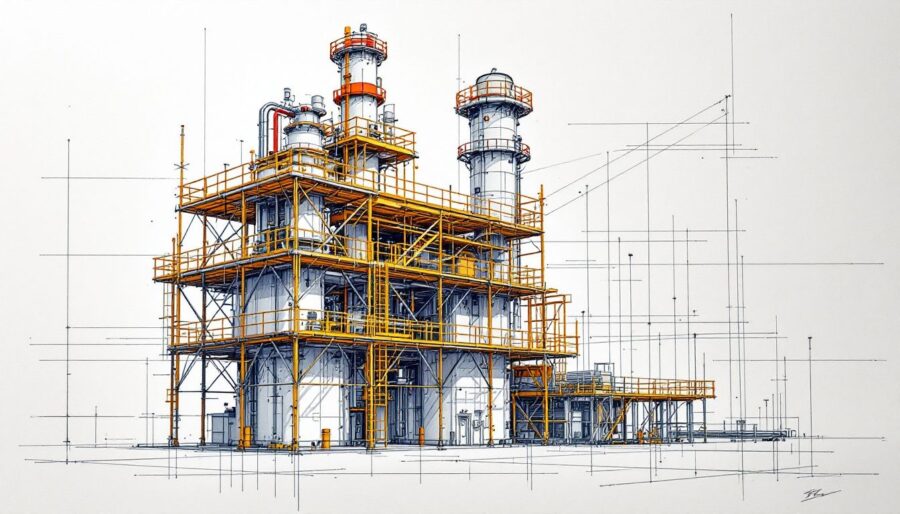

- Finalization of Modularization Plans: Modularization or prefabrication strategies are incorporated into procurement and construction schedules.

- Vendor and Material Reviews: Constructability teams review vendor drawings and material specifications to ensure alignment with field needs.

Key Deliverables:

- Issued for Construction (IFC) drawings with constructability inputs.

- Comprehensive modularization or prefabrication plans.

- Vendor drawings and procurement alignment.

Summary of Constructability Across Project Phases

| Phase | Constructability Focus | Key Deliverables |

|---|---|---|

| FEL-1 | Site selection, high-level execution strategies, and preliminary risk identification | Site evaluation reports, conceptual execution plans |

| FEL-2 | Site layout optimization, preliminary schedules, and regulatory feasibility | Layout studies, preliminary execution plans |

| FEL-3 | Detailed plot plans, heavy lift planning, and constructability workshops | Construction execution plans, modularization strategies |

| Detailed Design | Finalized 3D models, vendor drawing reviews, and prefabrication strategies | IFC drawings, procurement alignment plans |

Examples of Risk Management and Constructability

| Phase | Potential Risks Identified | Constructability Mitigation Strategies |

|---|---|---|

| FEL-1 | Site access issues, regulatory challenges | Early conceptual planning and feasibility studies |

| FEL-2 | Poor site layout, bottlenecks in schedule | Optimize layouts, incorporate feedback from teams |

| FEL-3 | Late-stage rework, heavy lift planning issues | Detailed workshops, logistics reviews |

| Detailed Design | Vendor misalignment, field welding accessibility | Vendor drawing reviews, modularization strategies |

Constructability Integration Based on Project Execution Approach

The integration of constructability varies depending on the chosen project execution method. Each approach Design-Bid-Build (DBB), Design-Build (DB), and Engineering, Procurement, and Construction (EPC) offers unique opportunities and challenges for embedding constructability.

Design-Bid-Build (DBB)

In the DBB model, constructability is typically introduced at key milestones during design development. Since construction expertise is often engaged later, ensuring constructability depends on:

- Conducting formal constructability reviews at 30%, 60%, and 90% design stages.

- Developing comprehensive execution plans that consider potential contractor input.

- Preemptively addressing potential constructability challenges through collaborative design workshops.

Design-Build (DB)

The DB approach inherently fosters early and continuous integration of constructability due to the collaborative structure of the project team. Benefits include:

- Early alignment of design and construction teams to optimize workflows.

- Real-time constructability input during design iterations, reducing rework.

- Enhanced ability to incorporate innovative solutions, such as modularization or prefabrication.

Enhancing Early Constructor Involvement in Design-Build

To maximize constructability benefits in the DB model, early constructor involvement is essential. Strategies include:

- Establishing Collaborative Design Teams: Design and construction teams should be integrated from project initiation, ensuring continuous input throughout design development.

- Implementing Progressive Design Reviews: Regular joint reviews allow constructors to provide feedback on constructability concerns and suggest design adjustments that enhance field execution.

- Leveraging Virtual Design and Construction (VDC): Tools such as 3D modeling and digital twins enable early visualization of design concepts, allowing constructors to identify and resolve potential issues before construction begins.

- Formalizing Early Engagement Contracts: Setting contractual obligations for early constructor participation ensures their involvement in critical design decisions.

Engineering, Procurement, and Construction (EPC)

In the EPC model, constructability is embedded across all phases, making it the most integrated approach. EPC projects benefit from:

- Seamless collaboration between engineering, procurement, and construction teams.

- Proactive identification of constructability opportunities during FEED and detailed design.

- Advanced work packaging (AWP) strategies that align engineering outputs with construction needs.

Constructability Tools and Best Practices

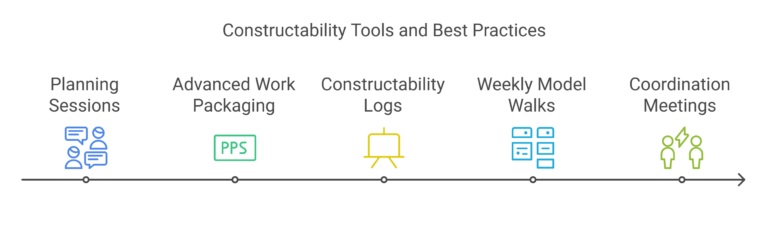

Planning Sessions

Planning sessions involve engineering, procurement, construction, and commissioning teams to develop aligned schedules and strategies. These sessions focus on:

- Collaborative schedule development.

- Agreement on sequencing and milestone dates.

- Identification of potential execution risks.

Advanced Work Packaging (AWP)

AWP structures the project into manageable packages, ensuring seamless integration from design through construction. Key components include:

- Construction Work Packages (CWPs) and Engineering Work Packages (EWPs).

- Alignment of 3D models with work packages.

- Coordination of procurement timelines with construction needs.

Constructability Logs

Maintaining a constructability log tracks suggestions and design changes, ensuring transparency and traceability. This tool:

- Captures value-adding ideas from all team members.

- Ensures accountability for implementation.

- Documents the impact of changes on cost, schedule, and safety.

Weekly Model Walks and Coordination Meetings

Weekly model walks allow teams to review design progress, identify conflicts, and align on key deliverables. Coordination meetings among disciplines ensure seamless collaboration and address challenges in real-time.

Summary of Best Practices

| Practice | Description | Benefits |

|---|---|---|

| Integrated Planning Sessions | Aligning schedules and strategies among all project disciplines | Reduces misalignment and delays |

| Advanced Work Packaging (AWP) | Structuring work into manageable packages | Streamlines execution and resource allocation |

| Constructability Logs | Tracking constructability suggestions and their implementation | Ensures transparency and measurable outcomes |

| Weekly Model Walks | Reviewing 3D models regularly to identify conflicts and align disciplines | Minimizes rework and improves safety |

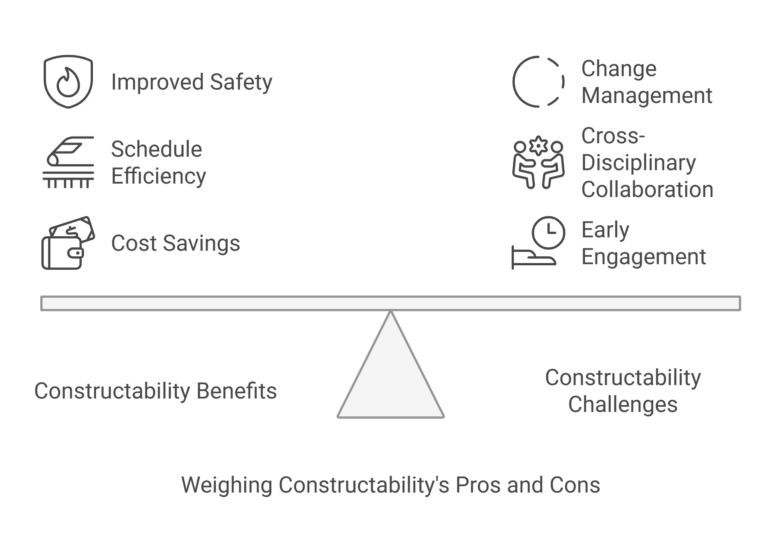

Constructability Benefits and Challenges

Benefits:

- Cost Savings: Reductions in labor, materials, and rework.

- Schedule Efficiency: Shortened critical paths and minimized delays.

- Improved Safety: Early identification and mitigation of potential hazards.

- Enhanced Quality: Robust designs aligned with construction realities.

- Innovation: Encouragement of creative solutions and methodologies that improve efficiency.

Challenges:

- Early Engagement: Success requires early and continuous involvement of construction expertise.

- Cross-Disciplinary Collaboration: Effective communication and alignment among diverse teams can be complex.

- Change Management: Integrating constructability may require adjustments to established workflows and processes.

Case Studies and Real-World Applications

Real-world examples demonstrate the value of constructability:

- Industrial Plant Expansion: Early constructability reviews identified opportunities to reduce heavy lift requirements through modularization, saving $5 million and two months on the schedule.

- Pipeline Project: A constructability-focused plot plan minimized access challenges, improving safety and reducing labor hours by 10%.

- Renewable Energy Facility: Prefabrication strategies incorporated during FEL-2 reduced onsite construction time by 20%, accelerating commissioning and achieving operational milestones ahead of schedule.

Conclusion

Constructability is essential to achieving optimal outcomes in industrial project development. By integrating construction expertise from FEL-1 through detailed design, teams can enhance safety, reduce costs, improve quality, and ensure schedule reliability.

The success of constructability integration depends significantly on the project execution approach. DBB projects benefit from structured review milestones to ensure construction practicality. DB and EPC models enable ongoing collaboration between design and construction teams, fostering innovation and efficiency through early alignment. In DB projects, early constructor involvement plays a pivotal role in aligning design and execution strategies, ensuring that constructability concerns are addressed proactively and opportunities for efficiency are maximized.

Leveraging best practices such as integrated planning sessions, AWP, and constructability logs enables seamless collaboration and innovation, delivering projects that meet or exceed client expectations. Constructability is not merely a technical practice but a holistic approach to project success, requiring commitment and collaboration across all phases and execution models. It represents a strategic investment in efficiency, quality, and safety, ensuring the successful delivery of complex industrial projects.

Disclaimer

The information provided in this post is for reference purposes only and is intended to serve as a guide to highlight key topics, considerations, and best practices. It does not constitute professional advice or a substitute for consulting regarding specific projects or circumstances. Readers are encouraged to evaluate their unique project needs and seek tailored advice where necessary. Please Contact Us to discuss your particular project.