Selecting the optimal project execution method is one of the most critical decisions for energy project success. The chosen method shapes the project’s cost, schedule, risk allocation, and overall efficiency. Whether it’s the traditional Design-Bid-Build (DBB) approach, the streamlined Design-Build (DB) model, or the comprehensive Engineering, Procurement, and Construction (EPC) framework, each execution strategy comes with unique advantages and challenges.

This guide explores the key execution methods, DBB, DB, EPC, Integrated Project Delivery (IPD), and Construction Management at Risk (CMAR), providing insights into their best-use scenarios, pros, and cons. By understanding these strategies, stakeholders can align execution methods with project goals to optimize outcomes and drive success in the energy sector.

Design-Bid-Build (DBB)

Overview:

Design-Bid-Build is the traditional project execution method where the project phases are separated into design, bidding, and construction. The owner hires a design team to complete detailed designs, and once finalized, solicits bids from contractors to execute the construction.

Pros:

- Clear Roles: Separation of design and construction responsibilities reduces conflicts of interest.

- Fixed Costs: Competitive bidding often results in lower costs.

- Design Precision: Detailed designs ensure a clear scope before construction begins.

Cons:

- Longer Timelines: Sequential processes delay project delivery.

- Potential Conflicts: Lack of collaboration between design and construction teams may lead to disputes or change orders.

- Limited Flexibility: Design adjustments during construction can be costly.

Best For:

Projects with well-defined scopes and minimal need for design adjustments, such as standard infrastructure projects.

Feature | Advantage | Disadvantage |

Roles & Responsibilities | Clear separation | Potential for disputes |

Cost | Often lower through bidding | Limited flexibility |

Schedule | Structured but slower | Sequential phases add delays |

Design-Build (DB)

Overview:

In the Design-Build model, a single entity is responsible for both design and construction, streamlining the process and improving collaboration. This execution type is similar to EPC (defined later) with the exception that the design and construction contracts are usually separate and executed at different times. In addition, the client usually bears the risk for design changes and executes certain parts of the project, such as long lead procurement and early construction scopes.

Pros:

- Faster Delivery: Overlapping design and construction phases reduce the schedule.

- Improved Collaboration: Single-point responsibility minimizes disputes.

- Cost Efficiency: Integration often leads to innovative solutions and cost savings.

Cons:

- Reduced Control: Owners may have less influence over design details.

- Risk of Oversights: Potential for reduced checks and balances.

- Dependency on Contractor: Success heavily depends on the selected Design-Build team’s expertise.

Best For:

Projects with tight schedules or where collaboration can drive value, such as renewable energy facilities or industrial plants.

Feature | Advantage | Disadvantage |

Collaboration | Streamlined | Reliant on contractor |

Cost | Often lower overall | Potential for oversight |

Schedule | Reduced duration | Reduced owner control |

Engineering, Procurement, and Construction (EPC)

Overview:

The EPC model assigns a single contractor full responsibility for engineering, procurement, and construction. This is a turnkey approach where the contractor delivers a complete, operational facility.

Pros:

- Turnkey Solution: Simplifies owner involvement.

- Fixed Price: Reduces financial uncertainty.

- Accountability: Single point of responsibility mitigates coordination issues.

Cons:

- Higher Initial Costs: EPC contractors may charge a premium for taking on more risk.

- Limited Flexibility: Changes during execution can be expensive.

- Reliance on Contractor: Requires trust in the contractor’s expertise.

Best For:

Large-scale, complex projects requiring minimal owner intervention, such as oil refineries or power plants.

Feature | Advantage | Disadvantage |

Risk Allocation | Simplified | Higher initial costs |

Flexibility | Streamlined | Limited mid-project changes |

Owner Involvement | Minimal | Reliant on contractor |

Integrated Project Delivery (IPD)

Overview:

IPD is a collaborative approach where all stakeholders—owners, designers, contractors, and suppliers—share risks and rewards, promoting alignment and efficiency.

Pros:

- Enhanced Collaboration: Promotes teamwork and innovation.

- Risk Sharing: Encourages collective problem-solving.

- Optimized Performance: Aligns all parties to achieve project goals.

Cons:

- Complex Contracts: Requires detailed agreements and trust among parties.

- High Coordination Needs: Demands significant upfront planning.

- Limited Market Familiarity: May be less common in certain regions or industries.

Best For:

Projects with a high degree of complexity and uncertainty, where collaboration can drive better outcomes, such as advanced manufacturing facilities.

Feature | Advantage | Disadvantage |

Collaboration | Strong alignment | High coordination demand |

Risk Distribution | Shared | Complex contractual needs |

Innovation | Promoted through synergy | Less common approach |

Construction Management at Risk (CMAR)

Overview:

In CMAR, the owner hires a construction manager (CMAR contractor) who provides pre-construction services and manages the construction phase. The CMAR contractor works closely with the owner and the design team to provide input during the design phase and guarantees a maximum price for the project. Engineering is typically handled by a design firm hired by the owner, while the CMAR contractor oversees construction, often engaging subcontractors for execution.

Pros:

- Cost Control: Guaranteed maximum price limits budget overruns.

- Flexibility: Allows for design adjustments during pre-construction.

- Owner Involvement: Owners retain significant control.

Cons:

- Higher Pre-Construction Costs: May involve more upfront expenses.

- Complex Coordination: Requires strong collaboration among parties.

- Risk Management: Owner still bears some risks.

Best For:

Projects where cost certainty is essential but the owner wants to stay actively involved, such as hospital expansions or educational facilities.

Feature | Advantage | Disadvantage |

Cost Control | Guaranteed price | Higher upfront costs |

Owner Involvement | Retained | Complexity in coordination |

Flexibility | Pre-construction adjustments | Shared risks |

Overall Summary of Project Execution Types

Execution Method | Key Advantages | Key Disadvantages | Best For |

Design-Bid-Build | Clear roles, fixed costs | Longer timelines, limited flexibility | Well-defined, standard projects |

Design-Build | Faster delivery, collaboration | Reduced owner control | Projects needing innovation and speed |

EPC | Turnkey, single accountability | Higher initial costs | Large, complex projects |

IPD | Collaboration, risk sharing | Complex contracts | Complex, uncertain projects |

CMAR | Cost control, owner involvement | Higher pre-construction costs | Projects needing owner engagement |

Note: The list above references the most common execution types. There are derivatives of each type, as well as other types that are less commonly used.

Note on Contract Types

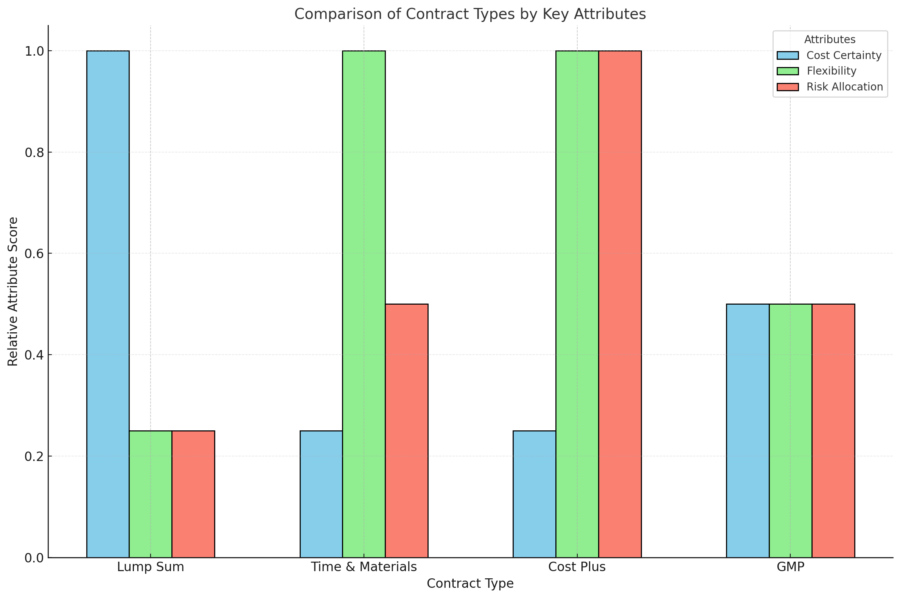

It is also important to consider the contract type when determining a project execution strategy. Common contract types include Lump Sum, Time and Materials (T&M), Cost Plus, and Guaranteed Maximum Price (GMP). Each has unique implications for risk allocation, cost control, and flexibility. These contract types are explored in greater detail here.

Conclusion

Each project execution method offers distinct advantages and challenges. The optimal choice depends on the project’s size, complexity, timeline, budget constraints, and the owner’s desired level of involvement. By understanding these execution strategies and their nuances, stakeholders can make informed decisions to achieve project success.

Appendix

Overall Summary Table of Contract Types and Execution Models

Contract Type | Cost Certainty | Flexibility | Risk Allocation | Common Execution Models |

Lump Sum | High | Low | Contractor | Design-Bid-Build, EPC |

Time & Materials | Low | High | Shared | CMAR, IPD |

Cost Plus | Low | High | Client | IPD, CMAR |

GMP | Moderate-High | Moderate | Shared | CMAR, IPD |

- Cost Certainty: Higher certainty is represented by higher scores (e.g., "High" = 1.0).

- Flexibility: Higher flexibility corresponds to higher scores.

- Risk Allocation: Reflects whether risk is shared, placed on the contractor "Low", or the client "High".

Disclaimer

The information provided in this post is for reference purposes only and is intended to serve as a guide to highlight key topics, considerations, and best practices. It does not constitute professional advice or a substitute for consulting regarding specific projects or circumstances. Readers are encouraged to evaluate their unique project needs and seek tailored advice where necessary. Please Contact Us to discuss your particular project.