Engineering, Procurement, and Construction (EPC) project execution has emerged as the dominant delivery model for large-scale energy projects in sectors such as oil and gas, renewables, and power generation. This method integrates all phases of a project: engineering, procurement, and construction, under a single contract, which allows for streamlined coordination, enhanced accountability, and greater efficiency. For energy companies navigating increasingly complex projects, the EPC model provides a one-stop solution that aligns stakeholders, reduces risks, and accelerates timelines.

Why does EPC execution matter so much in today’s energy sector? The industry is under constant pressure to meet ambitious climate goals, adapt to fluctuating market demands, and deliver projects on time and within budget. These challenges make it critical to adopt delivery models that not only optimize efficiency but also ensure quality and safety. EPC’s integrated approach has demonstrated measurable benefits, from cutting costs to reducing project risks.

In this article, we explore the effectiveness of EPC execution by delving into key statistics, analyzing real-world case studies, and addressing the challenges and opportunities inherent in this delivery model. Whether you’re a project owner, contractor, or stakeholder in the energy industry, the data presented here will underscore why EPC execution is not just a methodology but a strategic advantage.

Faster Project Delivery

In energy projects, time is money. Delayed project delivery can cost millions in lost revenue and opportunity. One of EPC’s key strengths is its ability to compress project schedules by integrating engineering, procurement, and construction.

Key Stats on Time Savings

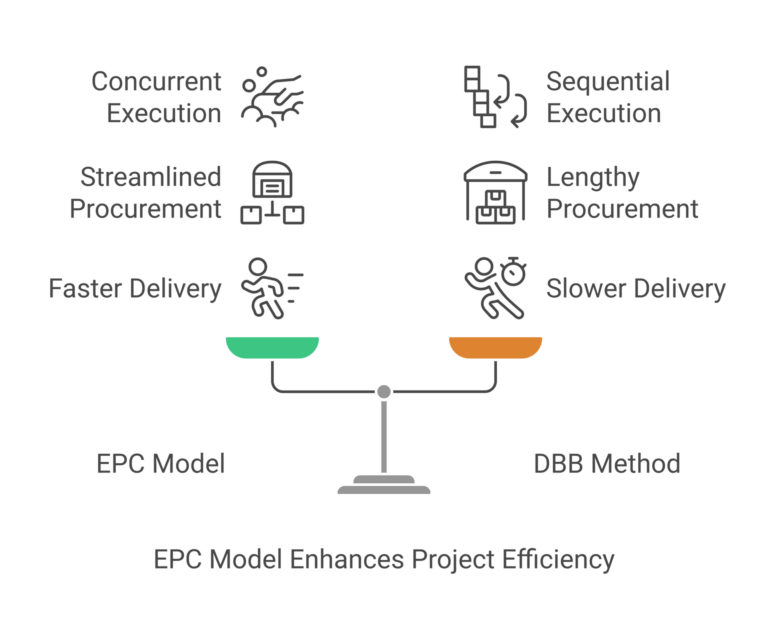

- 20-30% Faster Delivery: A 2022 Construction Industry Institute (CII) study found that EPC execution reduced overall project timelines by an average of 20-30% compared to traditional Design-Bid-Build (DBB) methods.

- Streamlined Procurement: According to McKinsey, centralized procurement under the EPC model decreases vendor selection and material acquisition times by 15%.

- Concurrent Execution: Deloitte reports that EPC projects using concurrent engineering and construction techniques can cut project timelines by as much as 25%.

Real-World Example

A Middle Eastern gas processing plant delivered under an EPC contract was completed 22% faster than initially estimated, achieving first production six months ahead of schedule. This allowed the client to avoid costly production delays and capture early market share.

Challenges

Despite the time-saving benefits, tight integration requires robust planning. Without clear workflows and communication between teams, schedule overruns can occur. To combat this, leading EPC firms leverage advanced scheduling software and real-time progress tracking tools like Primavera P6 or Oracle Cloud.

Summary

Metric | Traditional DBB | EPC Execution | Improvement |

Average Project Timeline | 36 months | 28-30 months | 20-30% faster |

Procurement Time Reduction | – | 15% | Centralized procurement |

Concurrent Engineering | – | Up to 25% faster | Parallel task execution |

Enhanced Cost Efficiency

Cost overruns are a major concern in energy projects, with 80% of large projects exceeding their budgets, according to a 2021 PwC report. EPC execution addresses this challenge by creating predictable cost structures through fixed-price contracts and centralized management.

Key Stats on Cost Efficiency

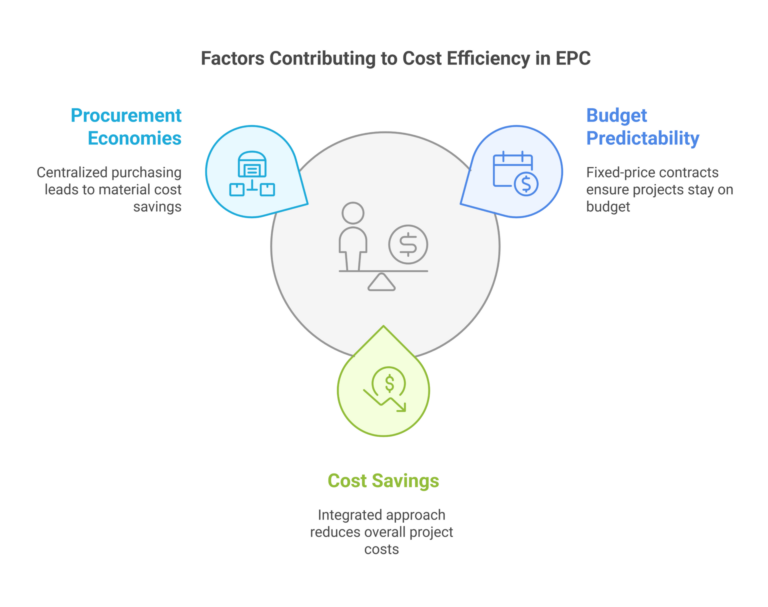

- Budget Predictability: Fixed-price EPC contracts keep 91% of projects on budget, compared to just 78% for DBB projects (CII 2023).

- Cost Savings: The integrated approach of EPC reduces overall project costs by 10-15%, per a PwC analysis.

- Procurement Economies of Scale: Centralized bulk purchasing under EPC contracts yields average material cost savings of 8-10%.

Real-World Example

A Southeast Asian oil refinery project saved over $50 million by consolidating procurement activities under a single EPC contractor. Bulk purchases of steel and piping materials allowed the contractor to negotiate steep discounts, directly benefiting the client.

The Hidden Benefits

EPC contracts shield owners from unforeseen expenses by transferring risks (such as material cost inflation or construction delays) to the contractor. However, owners must carefully evaluate contractors’ financial stability to avoid risks associated with contractor insolvency.

Summary

Metric | Traditional DBB | EPC Execution | Savings |

Budget Predictability | 78% on budget | 91% on budget | Fixed-price contracts |

Procurement Costs | Standard | Bulk discounts | 8-10% material savings |

Overall Project Costs | – | Reduced by 10-15% | Integrated management |

Improved Risk Management

Risk is inevitable in large-scale projects. EPC execution minimizes these risks by consolidating accountability under a single contractor, streamlining communication, and implementing proactive mitigation strategies.

Key Stats on Risk Management

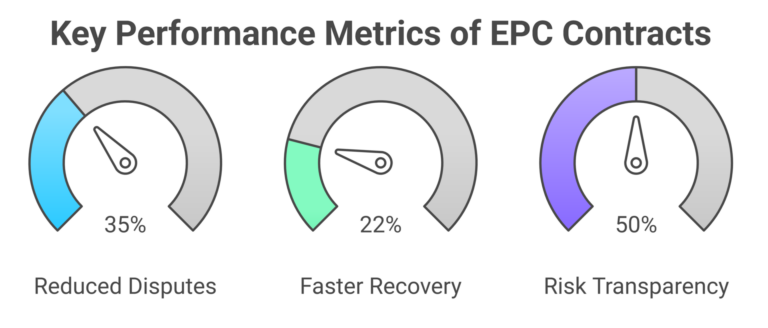

- Reduced Disputes: Projects delivered via EPC contracts experience 35% fewer contractor-owner disputes, according to a 2022 IPMA report.

- Faster Recovery: EPC contractors demonstrate 22% faster recovery from disruptions caused by supply chain issues or geopolitical risks.

- Risk Transparency: Deloitte’s 2023 study found that EPC projects achieve 50% higher alignment on risk management strategies among stakeholders.

Real-World Example

During the COVID-19 pandemic, an EPC contractor for a European wind farm mitigated supply chain disruptions by leveraging pre-negotiated agreements with alternative suppliers. This proactive approach avoided a $10 million penalty for project delays.

Key Takeaway

The risk mitigation benefits of EPC execution are amplified when contractors use advanced risk analysis tools like Monte Carlo simulations and risk registers. Owners should ensure contractors demonstrate strong risk management capabilities during the bidding process.

Summary

Metric | Non-EPC Projects | EPC Projects | Key Advantage |

Disputes | Frequent | 35% fewer disputes | Single-point accountability |

Recovery Time | Standard | 22% faster recovery | Pre-negotiated supplier terms |

Stakeholder Risk Alignment | 50% lower | 50% higher alignment | Consolidated risk strategies |

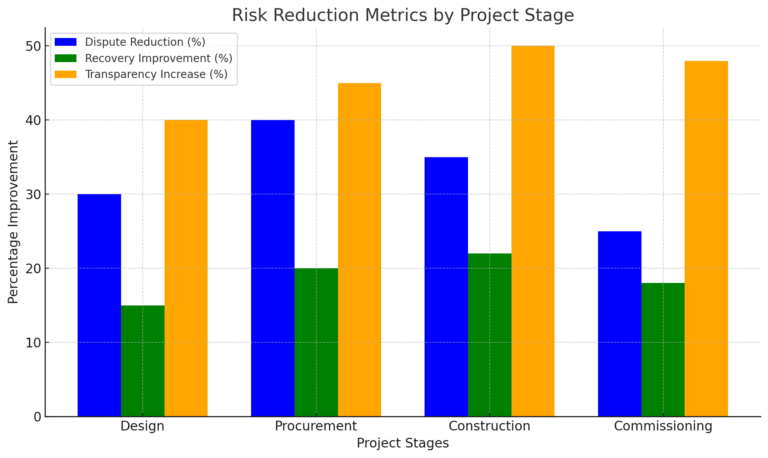

The graph above highlights how EPC execution effectively mitigates key risks at each stage of a project. For example, dispute reduction is most significant during procurement and construction, where 40% fewer issues arise due to centralized accountability. Recovery improvements, such as faster resolution of disruptions, peak during construction at 22%. Transparency increases consistently across all stages, with a 50% improvement during commissioning, ensuring better stakeholder alignment and smoother project transitions. This visualization underscores EPC’s strength in proactively managing risks throughout a project’s lifecycle.

Superior Quality Control

One of the hallmarks of successful EPC execution is high-quality outcomes. By centralizing responsibility, EPC models minimize errors and streamline inspections, ensuring deliverables meet or exceed client expectations.

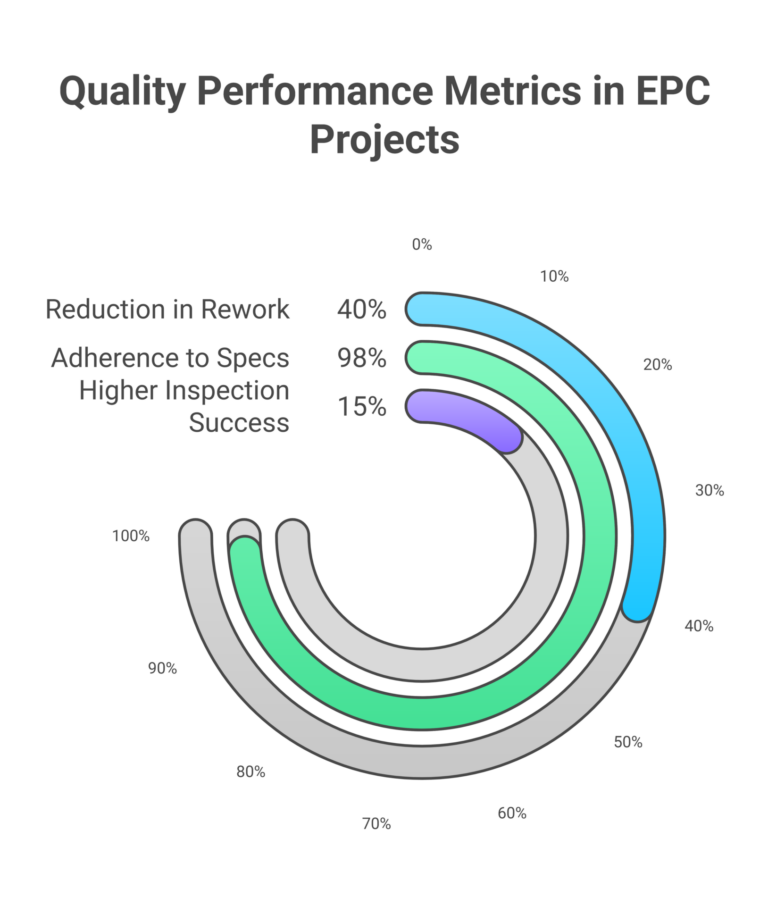

Key Stats on Quality

- Reduction in Rework: EPC projects report 40% fewer rework incidents compared to DBB models (Engineering Advancement Institute, 2023).

- Adherence to Specs: According to a CII study, EPC projects achieve 98% compliance with technical specifications on the first attempt.

- Higher Inspection Success: Third-party inspections during commissioning phases are 15% more successful in EPC projects.

Real-World Example

A U.S.-based chemical manufacturing facility achieved operational efficiency rates of 99.5% upon startup, a testament to the rigorous quality assurance protocols enforced by the EPC contractor.

Lessons Learned

Strong quality control requires detailed scopes of work and clear deliverables. Regular site inspections and non-conformance reporting should be part of every EPC contract to avoid surprises during commissioning.

Summary

Metric | DBB Model | EPC Model | Improvement |

Rework Incidents | High | 40% fewer incidents | Integrated engineering phases |

Compliance with Specs | Lower compliance | 98% first-time success | Centralized accountability |

Inspection Success | Lower success rate | 15% higher success | Streamlined quality controls |

Environmental and Safety Performance

With increasing regulatory pressure and stakeholder expectations, environmental and safety performance are critical metrics for energy projects. EPC execution promotes better compliance by integrating environmental and safety considerations into project design and execution.

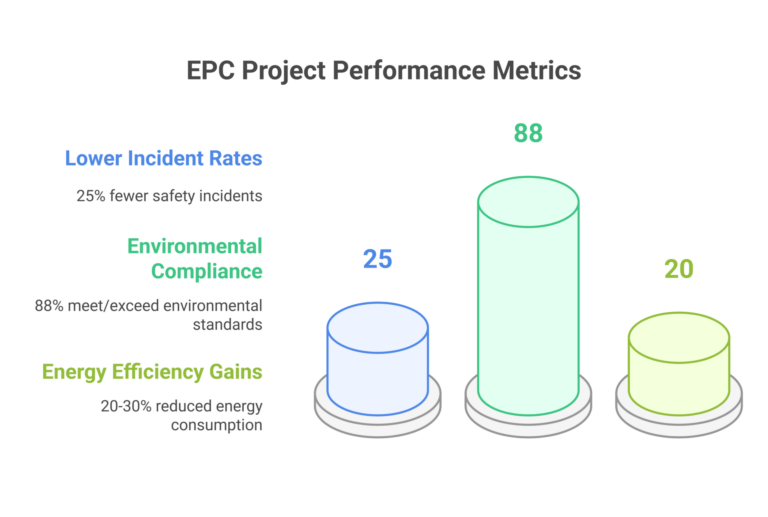

Key Stats on Safety and Environmental Performance

- Lower Incident Rates: EPC projects experience 25% fewer safety incidents than non-EPC projects (Global Construction Safety Report, 2022).

- Environmental Compliance: A World Bank study found that 88% of EPC projects meet or exceed environmental standards, compared to 70% for DBB projects.

- Energy Efficiency Gains: Sustainability-focused EPC firms reduced operational energy consumption by 20-30% in 2023 projects.

Real-World Example

An Australian renewable energy developer utilized EPC execution to build a wind farm that reduced carbon emissions by 500,000 metric tons annually, contributing significantly to regional climate goals.

Summary

Metric | Non-EPC Projects | EPC Projects | Improvement |

Safety Incident Rates | Higher | 25% fewer incidents | Integrated safety planning |

Environmental Compliance | 70% | 88% | Enhanced design integration |

Energy Efficiency Gains | Standard | 20-30% improvement | Sustainability-focused firms |

Scalability and Flexibility

EPC models are adaptable to a wide range of project sizes and complexities, making them ideal for industries with rapidly evolving needs.

Key Stats on Scalability

- Global Adoption: Over 65% of large-scale energy and infrastructure projects now use the EPC model (Statista 2023).

- Renewables Focus: More than 50% of solar and wind projects adopted the EPC model in 2023 (Renewable Energy Institute).

- Project Value Range: EPC execution has been used successfully on projects ranging from $5 million to $10 billion.

Real-World Example

A small-scale biogas facility in Africa costing $10 million and a $5 billion LNG plant in Qatar both successfully utilized EPC execution, highlighting the model’s versatility.

Summary

Technology | Benefit | Improvement |

Building Information Modeling (BIM) | 43% faster design approvals | Fewer construction errors |

IoT Monitoring | Real-time schedule adherence | 20% improvement |

AI Risk Management | Predictive analytics integration | 15% delay reduction |

Enhanced Client Satisfaction

EPC execution simplifies communication for project owners by providing a single point of contact. This approach reduces complexity and fosters better outcomes.

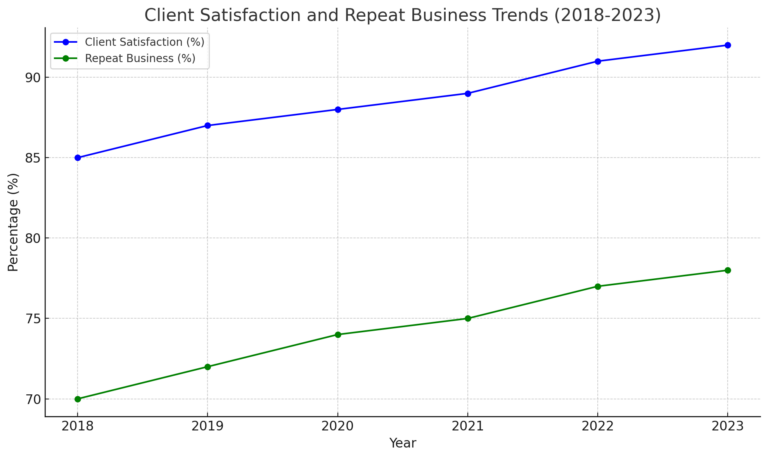

Key Stats on Client Satisfaction

- High Ratings: 92% of project owners rated their experience with EPC execution as “positive” or “very positive” (IPMA, 2022).

- Repeat Business: 78% of project owners who used EPC contractors returned to the same contractor for subsequent projects (Deloitte, 2022).

Real-World Example

A petrochemical company in Texas reported a 15% increase in operational efficiency after using an EPC contractor to expand its facilities, leading to additional collaborations with the same contractor.

Summary

Metric | Data | Impact |

Client Ratings | 92% Positive or Very Positive | High satisfaction due to simplicity |

Repeat Business Rate | 78% | Demonstrates trust and proven results |

Efficiency Improvements | 15% increase | Improved operational performance |

The client satisfaction trends graph illustrates the steady improvement in both satisfaction ratings and repeat business in EPC projects from 2018 to 2023. Satisfaction rates climbed from 85% in 2018 to 92% in 2023, reflecting the reliability and efficiency of the EPC model. Similarly, the repeat business rate rose from 70% to 78% over the same period, showcasing increased client trust and long-term partnerships fostered by consistent project success and streamlined communication. This growth underscores the value EPC execution brings in creating lasting relationships and meeting client expectations.

Digital Innovations in EPC Execution

Digital transformation has revolutionized EPC execution, enhancing productivity and reducing risks.

Key Stats on Digital Adoption

- BIM Efficiency: EPC firms using Building Information Modeling (BIM) achieved 43% faster design approvals and 30% fewer errors during construction (McKinsey, 2023).

- IoT Monitoring: Real-time IoT monitoring on EPC sites improved schedule adherence by 20% (Capgemini, 2023).

- AI in Risk Management: Predictive analytics reduced project delays by 15% in projects using AI-based tools (PwC).

Real-World Example

A Canadian mining project leveraged BIM to detect and resolve 150 design conflicts before construction began, saving $12 million in potential rework costs.

Summary

Technology | Functionality | Benefits | Impact |

Building Information Modeling (BIM) | Virtual 3D design and simulation | Faster approvals, fewer errors | 43% faster approvals, 30% fewer errors |

IoT Monitoring | Real-time site tracking | Improved adherence to schedules | 20% better schedule compliance |

AI Risk Management | Predictive analytics | Proactive risk identification | 15% reduction in delays |

Conclusion

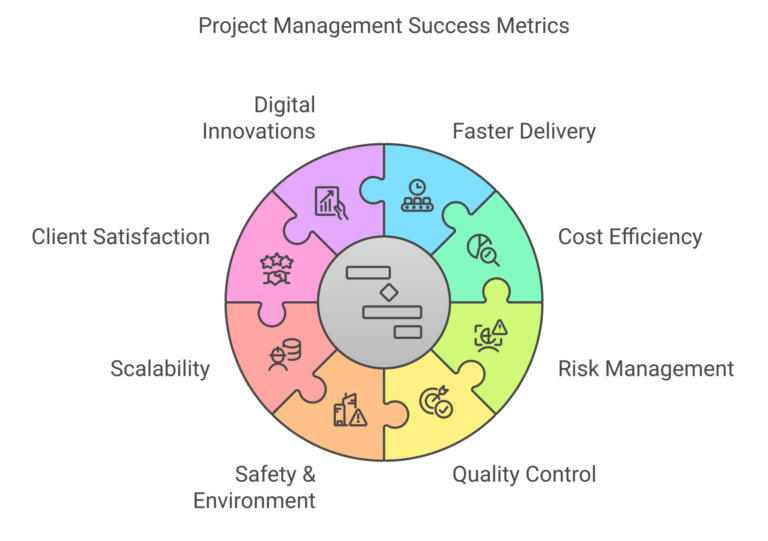

EPC execution stands as a proven model for delivering large-scale energy projects, combining faster timelines, cost efficiencies, superior quality, and robust risk management. The statistics reveal a clear advantage for project owners who adopt this integrated approach.

EPC By the Numbers Recap:

Key Area | Highlights | Impact |

Faster Delivery | 20-30% faster project timelines | Saves time and captures early revenue |

Cost Efficiency | 10-15% cost savings; 91% projects on budget | Reduces financial risks and overruns |

Risk Management | 35% fewer disputes; 22% faster disruption recovery | Enhances project stability and outcomes |

Quality Control | 40% fewer rework incidents; 98% compliance on first try | Ensures high standards and fewer delays |

Safety & Environment | 25% fewer incidents; 88% environmental compliance | Improves safety and meets regulations |

Scalability | Used for projects from $5M to $10B; 65% global adoption | Adapts to projects of all sizes |

Client Satisfaction | 92% positive ratings; 78% repeat business | Builds trust and long-term partnerships |

Digital Innovations | BIM: 43% faster design; IoT: 20% better adherence | Boosts efficiency and reduces errors |

As global demand for complex energy infrastructure grows, EPC execution will remain a cornerstone of success. Let the numbers speak for themselves: EPC is not just a method, it’s a competitive advantage.

Disclaimer

The information provided in this post is for reference purposes only and is intended to serve as a guide to highlight key topics, considerations, and best practices. It does not constitute professional advice or a substitute for consulting regarding specific projects or circumstances. Readers are encouraged to evaluate their unique project needs and seek tailored advice where necessary. Please Contact Us to discuss your particular project.