In the world of energy projects, where budgets often reach hundreds of millions or even billions of dollars, long-term planning is critical. However, one hidden risk can quietly derail even the most well-constructed plans: cost escalation. This often-overlooked factor, driven by inflation, market volatility, and supply chain disruptions, can lead to significant budget overruns, strained stakeholder relationships, and project delays.

Unlike contingencies that address project-specific uncertainties, escalation reflects the broader economic forces that inevitably affect labor, materials, and equipment costs over time. Neglecting to incorporate escalation into cost estimates can leave projects vulnerable to financial shortfalls and reactive decision-making. By understanding why escalation matters and proactively managing its impact, project teams can protect budgets, build stakeholder confidence, and navigate the uncertainties of long-term projects with greater resilience.

In this article, we’ll explore the hidden risks associated with escalation, the key drivers behind cost increases, and practical strategies to integrate escalation into long-term project planning. From defining escalation rates to leveraging scenario analysis and industry tools, we’ll provide actionable insights to help teams stay ahead of this critical challenge.

What is Cost Escalation?

Cost escalation is the predicted increase in project costs due to external factors such as inflation, supply chain disruptions, and changes in labor and material costs. Unlike contingencies, which account for project-specific uncertainties, escalation reflects broader economic trends.

Escalation is particularly critical for long-duration energy projects, where a delay in the procurement of materials or services can result in significant price changes over time.

Why is Escalation Critical in Cost Estimating?

Budget Accuracy

Ignoring escalation leads to underestimated budgets, creating unrealistic expectations and financial shortfalls.

Risk Mitigation

Proactively accounting for escalation reduces the risk of cost overruns caused by external economic conditions.

Stakeholder Trust

Transparent escalation assumptions build confidence among clients, contractors, and investors by demonstrating foresight and competence.

Strategic Procurement

Accurate escalation forecasts help procurement teams secure favorable contracts and lock in prices when market conditions are stable.

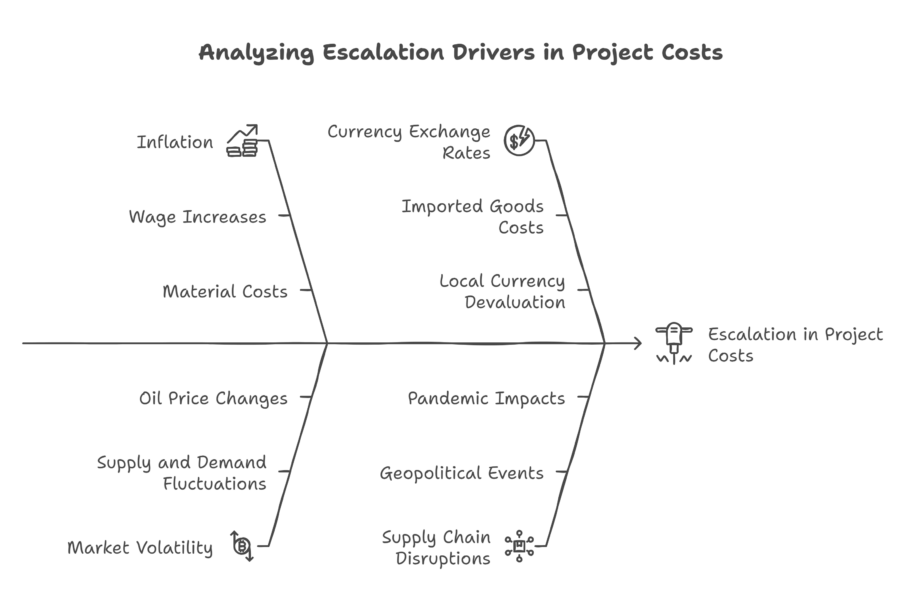

Key Drivers of Escalation

Inflation: General increase in prices over time, affecting wages, materials, and equipment. Steel prices increasing by 5% annually due to inflationary trends in global markets.

Market Volatility: Changes in supply and demand for specific commodities or labor markets. Fluctuating oil prices leading to increased costs for petrochemical plant construction.

Currency Exchange Rates: Variations in exchange rates affecting imported goods and services. Devaluation of a local currency raising the cost of imported equipment by 15%.

Supply Chain Disruptions: Delays or shortages caused by geopolitical events, pandemics, or natural disasters. Increased freight costs during the COVID-19 pandemic impacting material delivery timelines.

Labor Market Dynamics: Regional labor shortages or union negotiations driving up wage rates. A shortage of certified welders increasing labor costs for a pipeline project.

Integrating Escalation into Cost Estimates

Define Escalation Rates

Establish escalation rates for labor, materials, and equipment based on historical data, market research, and economic forecasts.

Cost Component Annual Escalation Rate (%) Source of Data

Labor 3–4% Regional wage growth trends

Steel 5–6% Historical steel price indices

Concrete 2–3% Construction material cost databases

Equipment 4–5% Vendor quotes and market forecasts

Apply Escalation to Time-Phased Budgets

Divide the project budget into phases (e.g., yearly or quarterly) and apply escalation rates to each phase.

Example Calculation:

- Base cost for steel: $1,000,000

- Escalation rate: 5% annually

- Project duration: 3 years

- Escalated cost = $1,000,000 × (1.05)^3 = $1,157,625

Use Scenario Analysis

Develop multiple scenarios (e.g., best-case, worst-case, and most-likely) to assess the potential impact of different escalation rates.

| Scenario | Steel Cost ($) | Labor Cost ($) | Total Escalated Cost ($) |

|---|---|---|---|

| Best Case | 1,100,000 | 2,000,000 | 3,100,000 |

| Most Likely | 1,157,625 | 2,060,000 | 3,217,625 |

| Worst Case | 1,200,000 | 2,120,000 | 3,320,000 |

Leverage Escalation Clauses in Contracts

Negotiate escalation clauses in procurement and contractor agreements to share the risk of price fluctuations.

Example:

A supplier agrees to a base price for steel but adjusts costs annually based on an agreed-upon market index, such as the ENR Construction Cost Index.

Monitor and Adjust Estimates

Regularly review escalation assumptions and update estimates to reflect changing market conditions.

Tools for Monitoring

- Producer Price Index (PPI): Tracks price changes for goods and services.

- Commodity Price Forecasts: Predicts trends for materials like steel and copper.

- Labor Market Reports: Provides insights into regional wage trends.

Tools for Managing Escalation

Several software tools can help manage escalation in cost estimates by providing data integration, scenario modeling, and tracking capabilities.

Cleopatra Enterprise Integrated cost management with escalation forecasting, cost phasing, and risk analysis. Large-scale, multi-year industrial projects.

Primavera P6 Project scheduling and cost tracking with escalation modeling capabilities. Projects with complex schedules and resources.

AACE’s Cost Management Framework Standardized framework for estimating and managing escalation. Organizations looking for consistency across projects.

Procore Cloud-based platform for real-time collaboration and cost tracking. Collaborative projects with multiple stakeholders.

Excel with Add-Ins Customizable spreadsheets with escalation modeling formulas. Smaller projects or initial estimate phases.

Case Study: Managing Escalation in an Industrial Project

Project Overview

A petrochemical plant construction project valued at $500 million, with a five-year timeline.

Challenges

- Significant volatility in steel and labor costs.

- Currency fluctuations affecting imported equipment.

- Stakeholder concerns about budget overruns.

Escalation Strategy

- Define Rates:

- Steel: 6% annual escalation based on historical indices.

- Labor: 4% annual escalation derived from regional wage data.

- Apply to Time-Phased Budget:

- Steel procurement spread across years 2–4 of the project.

- Labor costs adjusted annually based on anticipated escalation.

- Incorporate Scenario Planning:

- Developed best-case, most-likely, and worst-case scenarios for cost projections.

- Monitor and Adjust:

- Regularly reviewed escalation rates against updated market data.

- Adjusted estimates and procurement schedules to lock in favorable prices when possible.

Outcome

The project was completed within 5% of the estimated budget, thanks to proactive escalation management and ongoing adjustments.

Challenges in Managing Escalation

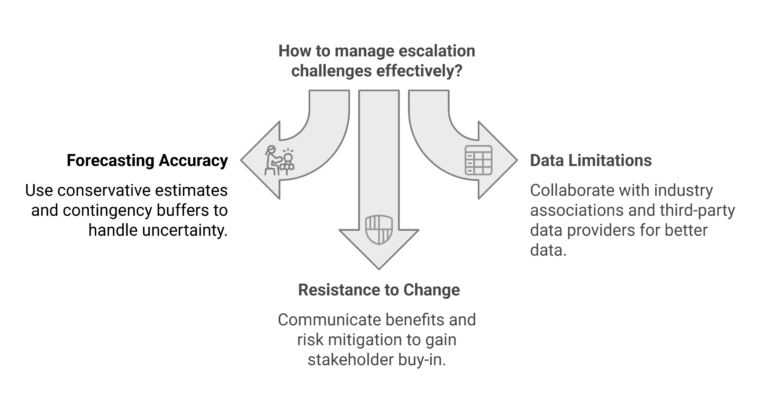

Forecasting Accuracy

Predicting future market conditions is inherently uncertain.

Solution: Use conservative estimates and build in contingency buffers for unanticipated increases.

Data Limitations

Limited access to reliable historical or regional data can hinder escalation forecasting.

Solution: Collaborate with industry associations and leverage third-party data providers.

Resistance to Change

Stakeholders may resist escalation provisions, viewing them as unnecessary.

Solution: Clearly communicate the rationale and benefits of accounting for escalation, emphasizing risk mitigation.

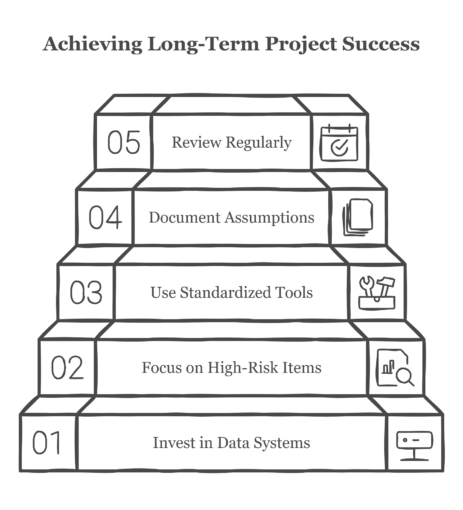

Best Practices for Long-Term Success

- Invest in Data Systems: Maintain a centralized database of historical project data to support benchmarking and escalation forecasting.

- Focus on High-Risk Items: Prioritize materials and resources most susceptible to price volatility.

- Use Standardized Tools: Implement platforms like Cleopatra Enterprise or Primavera for consistency and accuracy.

- Document Assumptions: Clearly record escalation assumptions for transparency and future reference.

- Review Regularly: Reassess escalation assumptions throughout the project lifecycle to reflect changing conditions.

Conclusion

Escalation is an inevitable aspect of cost estimating in industrial projects. By proactively managing escalation through accurate forecasting, robust tools, and collaborative strategies, project teams can mitigate financial risks, build stakeholder confidence, and achieve successful outcomes. In an industry where external economic factors can significantly impact budgets, integrating escalation into estimates is not just a best practice, it’s an essential element of strategic project management.

Disclaimer

The information provided in this post is for reference purposes only and is intended to serve as a guide to highlight key topics, considerations, and best practices. It does not constitute professional advice or a substitute for consulting regarding specific projects or circumstances. Readers are encouraged to evaluate their unique project needs and seek tailored advice where necessary. Please Contact Us to discuss your particular project.