As the energy transition accelerates, hydrogen is gaining traction as a key enabler of decarbonization across industrial sectors, heavy transport, and power generation. Two major hydrogen-powered technologies are emerging as front-runners: hydrogen combustion engines and hydrogen fuel cells. While both use hydrogen as a clean energy source, the way they generate power and the scenarios in which each excels are fundamentally different.

This article provides a comparative look at these two technologies, offering a background on how they work, the pros and cons of each, and where they best fit in real-world applications.

What Is a Hydrogen Combustion Engine?

A hydrogen combustion engine is a modified internal combustion engine (ICE) that burns hydrogen instead of gasoline or diesel. It functions in a similar way to a conventional engine. Hydrogen is injected into the combustion chamber, mixed with air, and ignited to produce mechanical power that drives the vehicle or equipment. The primary emissions are water vapor and trace amounts of nitrogen oxides (NOx), which may require aftertreatment to meet emissions standards. These engines are often based on existing ICE platforms, which makes them attractive for retrofits and rapid deployment in familiar settings.

What Is a Hydrogen Fuel Cell?

A hydrogen fuel cell generates electricity through an electrochemical process rather than combustion. Inside the fuel cell, hydrogen molecules are split into protons and electrons. The electrons flow through an external circuit to generate electricity, while the protons pass through a membrane and recombine with oxygen to form water. This process is highly efficient and produces only water vapor as a byproduct. Fuel cells are known for their quiet operation, high efficiency, and ability to support a range of vehicle sizes and power requirements.

Comparative Overview: Hydrogen Combustion vs. Hydrogen Fuel Cells

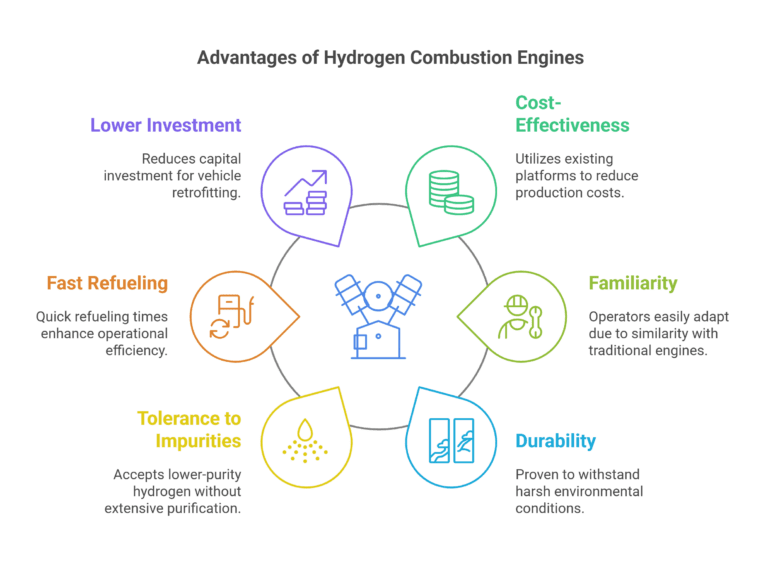

Pros of Hydrogen Combustion Engines

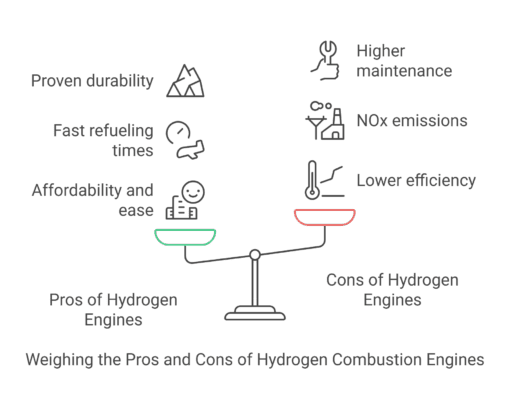

- Typically more affordable to produce due to reliance on existing internal combustion engine platforms and manufacturing infrastructure

- Easier adoption by operators and maintenance teams who are already familiar with traditional engine technology

- Proven durability in rugged environments with exposure to dust, heat, and cold, making them ideal for off-road and industrial applications

- More tolerant of lower-purity hydrogen, reducing the need for expensive fuel purification

- Fast refueling times and compatibility with existing fueling infrastructure

- Lower capital investment required for deployment and retrofitting of current vehicles or machinery

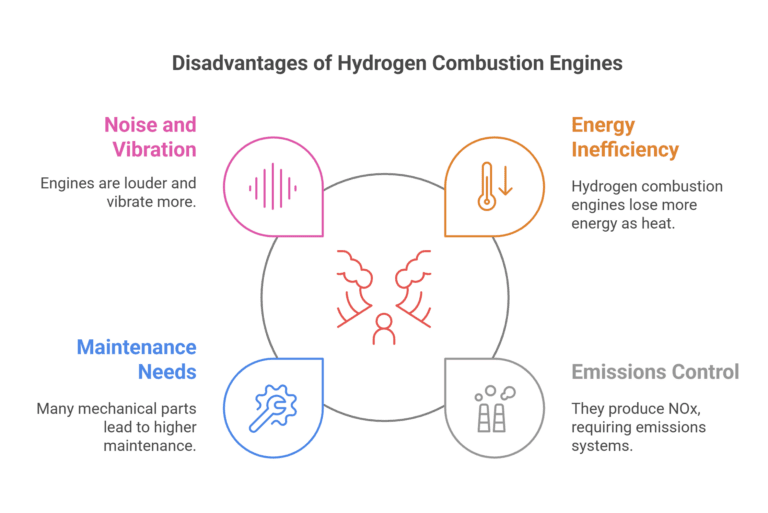

Cons of Hydrogen Combustion Engines

- Lower overall energy efficiency compared to hydrogen fuel cells, with more energy lost as heat

- Produces nitrogen oxides (NOx) as a byproduct, requiring emissions control systems

- Contains many mechanical parts subject to wear, leading to higher maintenance needs

- Louder operation and greater vibration levels make them less suitable for quiet or sensitive environments

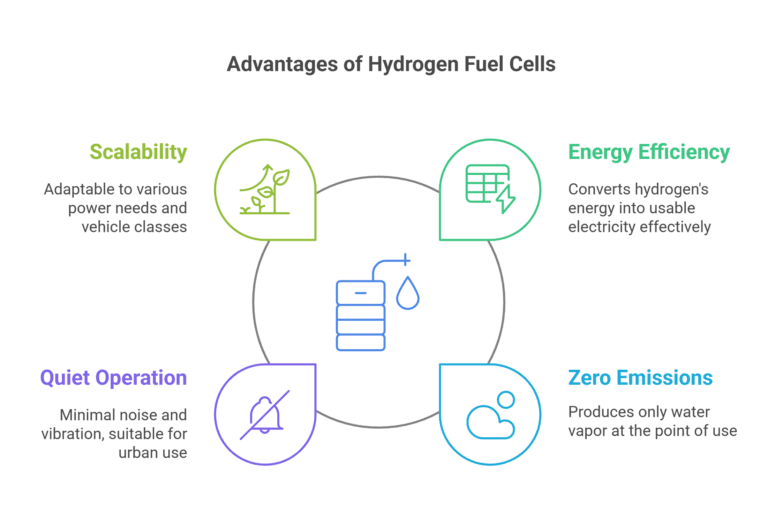

Pros of Hydrogen Fuel Cells

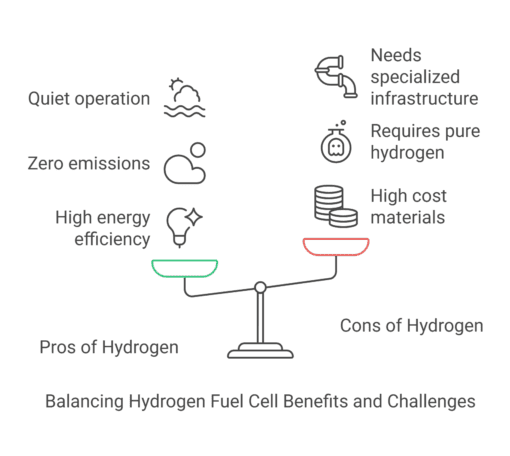

- High energy efficiency, converting more of hydrogen’s energy into usable electricity

- Zero emissions at the point of use, producing only water vapor

- Quiet operation with minimal vibration, ideal for urban or indoor settings

- Scalable and modular design allows for use across diverse power needs and vehicle classes

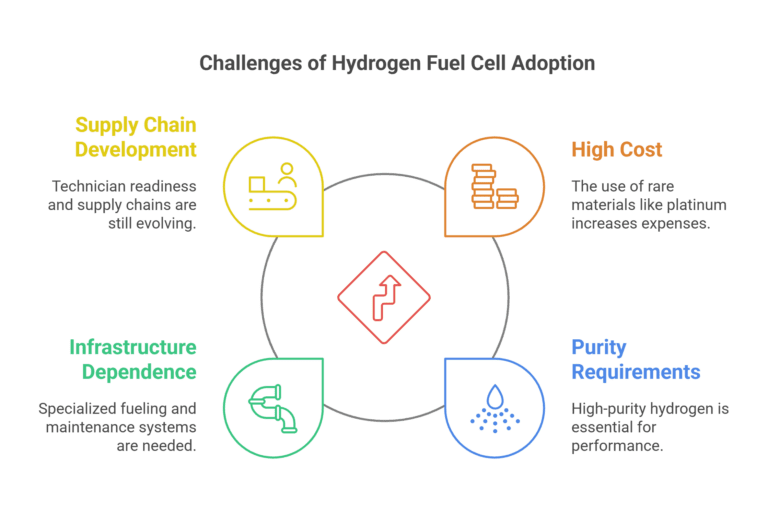

Cons of Hydrogen Fuel Cells

- High cost due to the use of rare and expensive materials like platinum

- Requires high-purity hydrogen to avoid degradation and maintain performance

- Dependent on specialized infrastructure for fueling and trained technicians for maintenance

- Supply chain and technician readiness are still developing, slowing down large-scale deployment

Infrastructure and Fueling Considerations

The successful deployment of hydrogen-powered technologies depends heavily on infrastructure and fueling capabilities. Hydrogen fuel cells require dedicated high-pressure refueling stations that dispense hydrogen at purity levels of 99.999 percent or higher. These stations are costly to develop and are currently limited in number, particularly outside of densely populated or highly industrialized areas. As a result, adoption of fuel cell vehicles is often constrained by the availability of compatible infrastructure.

Hydrogen combustion engines, on the other hand, offer greater flexibility when it comes to fueling infrastructure. Because they are less sensitive to hydrogen purity, they can operate effectively with hydrogen produced through lower-cost and less refined methods. In many cases, existing fueling infrastructure can be adapted to accommodate hydrogen combustion. This adaptability makes hydrogen combustion attractive in regions with limited infrastructure development, particularly where decentralized or on-site hydrogen production is available.

Additionally, hydrogen combustion systems can integrate more easily into current fueling workflows and support industries looking to transition incrementally. This gives hydrogen combustion engines a distinct advantage in terms of deployment speed and operational readiness.

Lifecycle Emissions and Hydrogen Source

While hydrogen combustion engines and fuel cells are both considered zero-emission technologies at the point of use, the overall environmental benefit depends on the source of hydrogen and the energy inputs used throughout its lifecycle. Hydrogen can be produced in a variety of ways, each with its own emissions profile.

Green hydrogen is produced through electrolysis powered by renewable electricity, such as solar or wind. This method results in the lowest lifecycle emissions and aligns with net-zero carbon targets. However, it is currently the most expensive form of hydrogen and accounts for a small portion of global production.

Grey hydrogen, which is derived from natural gas through a process called steam methane reforming, is the most common and economically viable option today. However, it is associated with high carbon emissions unless paired with carbon capture and storage (CCS) technologies, in which case it is classified as blue hydrogen.

Evaluating the full lifecycle emissions of hydrogen systems is critical for assessing their true sustainability. Projects that use green hydrogen offer the greatest environmental benefit, while those reliant on grey hydrogen must weigh emissions trade-offs against other practical considerations such as cost, availability, and scalability.

Capital and Operating Cost Considerations

Cost remains a key factor in determining the feasibility of hydrogen technologies. Hydrogen combustion engines benefit from using existing manufacturing lines, supply chains, and mechanical designs. This helps keep upfront capital costs relatively low. Retrofitting traditional internal combustion platforms for hydrogen use also minimizes new development expenses. On the operating side, maintenance is similar to diesel or gasoline engines, and fuel quality requirements are less strict, which can reduce costs.

Hydrogen fuel cells, in contrast, involve high upfront costs due to the need for specialized materials like platinum, advanced manufacturing processes, and proprietary system designs. Operating costs are influenced by the need for high-purity hydrogen, which is often more expensive to produce and distribute. Maintenance of fuel cells may also require specialized technicians and equipment, which adds to the total cost of ownership. However, fuel cells offer superior energy efficiency, which can lead to lower fuel consumption over time.

Understanding both capital and lifecycle costs is critical for fleet managers, policymakers, and investors who are evaluating hydrogen solutions for long-term adoption.

Safety and Handling Considerations

Hydrogen is a highly flammable gas, and its safe use requires adherence to strict protocols regardless of the technology employed. For hydrogen combustion engines, safety measures are largely similar to those used with traditional fuel systems, such as sealed fuel tanks, leak detection systems, and proper ventilation. These systems are often easier to integrate into existing platforms, and the technology to manage combustion safely is well understood in the automotive and industrial sectors.

Hydrogen fuel cells involve different risks, primarily related to the storage and dispensing of high-pressure hydrogen gas and the need for ultra-clean fuel delivery systems. The high-pressure storage tanks used in fuel cell vehicles (often rated at 700 bar) must meet rigorous standards and require careful inspection and maintenance. Additionally, fuel cell systems must manage hydrogen purity to prevent damage to sensitive catalysts and membranes.

Both systems benefit from ongoing advancements in hydrogen storage, leak detection, and emergency response protocols. However, fuel cells may face greater scrutiny in environments unfamiliar with their operational nuances, particularly due to their higher pressure systems and chemical sensitivities.

Educating users, technicians, and emergency personnel on proper hydrogen handling practices is essential for ensuring safe deployment of both combustion and fuel cell technologies.

Market Outlook and Adoption Forecast

Global demand for hydrogen is accelerating as governments and industries aim to decarbonize hard-to-electrify sectors. According to BloombergNEF, global hydrogen consumption could rise from approximately 90 million metric tons per year today to over 500 million metric tons by 2050. This growth will be driven by increased adoption in transport, heavy industry, power generation, and energy storage.

Hydrogen fuel cells are expected to dominate the light-duty and long-haul vehicle segments where high efficiency and zero emissions are critical, especially in regions with advanced infrastructure and policy support. Meanwhile, hydrogen combustion is projected to play a key role in industrial equipment, construction machinery, and retrofit applications due to its faster deployment, cost advantages, and compatibility with existing technology.

Major manufacturers such as Toyota, Hyundai, Nikola, Cummins, and JCB are already investing heavily in both fuel cell and combustion platforms. Their parallel development strategies reflect a growing consensus: both technologies are essential in creating a flexible, resilient, and low-emission hydrogen economy.

Comparison Table

Feature | Hydrogen Combustion Engine | Hydrogen Fuel Cell | Traditional Combustion Engine |

Energy Efficiency | Moderate (25 to 35 percent) | High (50 to 60 percent) | Low (20 to 30 percent) |

Emissions | Zero CO2, some NOx | Zero emissions | High CO2 and NOx |

Fuel Purity Requirements | Low | High | Low |

Maintenance Complexity | Moderate | High | Moderate |

Noise and Vibration | High | Very Low | High |

High | Moderate | Very High | |

Ideal Use Cases | Off-road, retrofits, harsh conditions | Urban fleets, long-haul transport | General transport, widespread use |

Use Case Scenarios

In construction and agriculture, equipment such as excavators, harvesters, and off-road utility vehicles often operate in remote and rugged locations. These environments benefit from the durability, quick refueling, and mechanical familiarity of hydrogen combustion engines.

Urban transit and delivery fleets operate in emissions-regulated areas where quiet operation is important. Fuel cell vehicles serve well in these roles by producing no tailpipe emissions and operating with minimal noise.

In heavy-duty long-haul transport, efficiency and range are key performance indicators. Hydrogen fuel cells provide a strong solution for Class 8 trucks and similar applications due to their higher efficiency and reduced emissions.

For remote industrial sites with limited infrastructure and irregular access to high-purity hydrogen, hydrogen combustion engines may be more practical. Their tolerance for fuel variability and ease of integration into existing platforms makes them an ideal transitional technology.

Regional and Policy Considerations

Regulatory frameworks have a strong influence on the adoption of hydrogen technologies. Regions like the European Union, California, and South Korea have implemented strict emissions regulations that favor the deployment of zero-emission fuel cell vehicles. These areas also tend to invest in the infrastructure needed to support fuel cell growth.

Conversely, regions with less stringent regulations or more industrial use cases may opt for hydrogen combustion engines as a near-term solution. These engines can achieve meaningful reductions in carbon emissions without requiring an overhaul of fueling networks or retraining of workforces.

Policymakers, manufacturers, and end users must consider infrastructure availability, total lifecycle emissions, and capital investment constraints when choosing between hydrogen combustion and hydrogen fuel cell technologies.

Summary

Hydrogen combustion engines and hydrogen fuel cells both serve as promising alternatives to fossil fuel-powered engines, each with their own unique benefits and challenges. Combustion engines offer a fast, cost-effective, and familiar path toward hydrogen adoption, especially in rugged, off-road, or transitional industrial settings. Fuel cells, by contrast, shine in applications where efficiency, emissions performance, and quiet operation are critical.

There is no universal solution that fits all use cases. Instead, each organization or jurisdiction must evaluate its technical, operational, and regulatory priorities to determine which technology best supports its decarbonization goals. Both hydrogen combustion and fuel cell systems will play vital roles in building a low-emissions energy future.

Disclaimer

The information provided in this post is for reference purposes only and is intended to serve as a guide to highlight key topics, considerations, and best practices. It does not constitute professional advice or a substitute for consulting regarding specific projects or circumstances. Readers are encouraged to evaluate their unique project needs and seek tailored advice where necessary. Please Contact Us to discuss your particular project.