Controlling costs in energy construction is one of the most significant challenges project teams face, particularly for large-scale projects with budgets often exceeding hundreds of millions of dollars. From accurate cost estimation to leveraging technology and effective procurement strategies, managing costs requires a combination of proven techniques and proactive planning. Mismanaged budgets can lead to financial overruns, project delays, and stakeholder dissatisfaction. By implementing effective cost control strategies throughout the project lifecycle, teams can ensure financial discipline, optimize resources, and achieve project success without compromising quality.

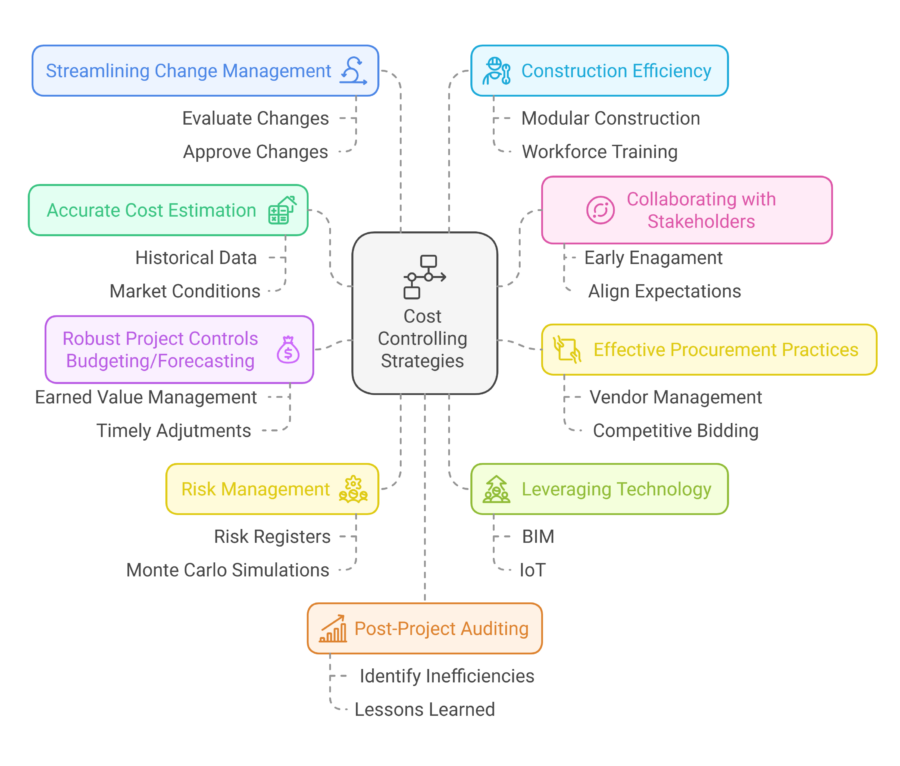

10 Cost Controlling Strategies

| Strategy | Description |

|---|---|

| 1. Accurate Cost Estimation from the Start | Use historical data, market conditions, and contingencies to set realistic budgets and avoid surprises. |

| 2. Budgeting and Forecasting | Combine static budgets with rolling forecasts to adapt to real-time changes and ensure financial alignment. |

| 3. Effective Procurement Practices | Leverage strategic vendor management, competitive bidding, and long-term contracts to control costs and ensure quality. |

| 4. Implementing Robust Project Controls | Use tools like Earned Value Management (EVM) to monitor cost performance and make timely adjustments. |

| 5. Risk Management and Mitigation | Identify, assess, and mitigate risks with tools like risk registers and Monte Carlo simulations. |

| 6. Leveraging Technology | Employ BIM, IoT, drones, and AI to enhance planning, reduce rework, and monitor resources efficiently. |

| 7. Streamlining Change Management | Implement structured processes to evaluate and approve scope changes, minimizing disruptions and cost impacts. |

| 8. Focusing on Construction Efficiency | Use modular construction, IoT monitoring, and workforce training to reduce labor costs, waste, and delays. |

| 9. Post-Project Auditing and Improvement | Conduct audits to identify inefficiencies, successes, and lessons learned for continuous organizational improvement. |

| 10. Collaborating with Stakeholders | Engage stakeholders early, maintain transparent communication, and align expectations to prevent disputes and rework. |

1. Accurate Cost Estimation from the Start

Cost estimation is the foundation of any successful project. A reliable estimate sets realistic expectations for stakeholders, provides a clear financial roadmap, and reduces the likelihood of budget surprises. Creating accurate estimates involves leveraging historical data, accounting for current market conditions, and planning for uncertainties with contingencies. Class 5 estimates provide rough order-of-magnitude costs during the early feasibility phase, while Class 3 or Class 2 estimates offer detailed accuracy as the project progresses.

Estimation errors often occur due to incomplete data, optimistic assumptions, or underestimating complexities. Ignoring risks or failing to allocate appropriate contingencies can result in significant overruns. Estimation processes must integrate technical, financial, and market perspectives to capture the full scope of costs. Collaborative input from engineers, procurement teams, and project managers is essential to ensure comprehensive and realistic cost forecasting.

Example:

An oil refinery expansion used historical cost data from similar projects to establish a baseline budget. Engineers validated these numbers with vendor quotes for large equipment like heat exchangers, ensuring realistic pricing.

2. Budgeting and Forecasting

Budgeting and forecasting are dynamic tools that guide financial decisions throughout a project. A well-crafted budget establishes the baseline financial framework, outlining how funds will be allocated across various project components. Forecasting, on the other hand, ensures that the budget remains relevant as project conditions evolve. Together, they provide a dual-layered approach to financial management: the budget serves as the static foundation, while forecasts adjust dynamically to account for real-time variables.

A static budget without ongoing forecasting can lead to significant deviations from planned expenditures, particularly in large projects where unexpected changes are common. Effective forecasting involves analyzing trends, identifying variances, and anticipating risks. By leveraging real-time data, forecasts help decision-makers make informed adjustments, ensuring that projects stay on track financially.

Example:

In a $500M solar farm project, monthly rolling forecasts detected a potential $8M labor cost overrun. By reallocating contingency funds and enhancing workforce training, the team mitigated the risk and avoided delays.

3. Effective Procurement Practices

Procurement is one of the most critical aspects of cost control in large-scale projects, often accounting for a significant portion of the budget. Effective procurement involves more than just acquiring materials and services; it requires strategic planning, vendor management, and contractual discipline. Competitive bidding processes, long-term supply agreements, and performance-based contracts are essential practices that minimize costs and ensure quality.

Failures in procurement can lead to delays, substandard materials, or budget overruns due to unplanned expenses. To mitigate these risks, procurement strategies should focus on selecting reliable vendors, locking in prices for critical components, and monitoring supplier performance throughout the project lifecycle. In addition, leveraging digital procurement platforms can streamline processes and provide transparency.

Example:

A natural gas facility negotiated bulk purchasing agreements for critical equipment, saving $5M. Long-term contracts locked in favorable prices and mitigated market fluctuations.

4. Implementing Robust Project Controls

Project controls are the mechanisms that ensure alignment between the project plan and actual performance. These controls monitor costs, schedules, and resources in real time, enabling proactive responses to variances. Without robust project controls, small inefficiencies can escalate into significant budget and timeline overruns, jeopardizing project success.

A comprehensive project control system integrates cost management with scheduling tools, ensuring that project teams have visibility into performance metrics such as Cost Performance Index (CPI) and Schedule Performance Index (SPI). These metrics provide insights into whether the project is staying within budget and on schedule. Additionally, centralized dashboards help stakeholders track progress and identify potential issues early.

Example:

In a refinery upgrade project, EVM metrics flagged delays in piping installation. Timely adjustments in resource allocation avoided $10M in labor cost overruns.

5. Risk Management and Mitigation

Risks are an inherent part of any large-scale project. From material cost fluctuations to weather disruptions and regulatory hurdles, unmanaged risks can result in delays, cost overruns, and reputational damage. Proactive risk management begins with identifying potential risks, assessing their likelihood and impact, and developing mitigation strategies. This process requires collaboration across project teams and stakeholders to ensure risks are understood and addressed comprehensively.

A key element of risk management is creating a dynamic risk register, which tracks potential issues, their impact, and the mitigation measures in place. Regular updates to the risk register ensure that teams remain prepared for evolving challenges. Quantitative tools like Monte Carlo simulations can provide deeper insights into the financial implications of risks, allowing for more effective contingency planning.

Example:

In an offshore wind project, a risk analysis identified severe weather as a major challenge. By scheduling critical activities during favorable seasons, the project avoided $15M in delays.

6. Leveraging Technology

Technology plays an essential role in modern project cost control by improving efficiency, accuracy, and communication. Tools like Building Information Modeling (BIM), drones, Internet of Things (IoT) sensors, and AI-based analytics have revolutionized project execution. BIM enables teams to visualize workflows and identify design conflicts before construction begins, reducing rework and saving significant costs. Similarly, drones provide real-time site monitoring, enhancing progress tracking and resource allocation.

The integration of technology also supports predictive analytics, which uses historical data and current trends to forecast potential risks, material shortages, or labor inefficiencies. AI tools can predict cost overruns, enabling project teams to take corrective action early. By adopting these advanced technologies, companies can achieve greater precision in project planning and execution, resulting in lower costs and better outcomes.

Example:

A petrochemical facility implemented BIM during the design phase, identifying conflicts that would have cost $10M in rework. Additionally, IoT sensors tracked material consumption, preventing over-ordering and saving $2M.

7. Streamlining Change Management

Change is inevitable in large-scale industrial projects, but unmanaged changes can disrupt schedules, inflate costs, and erode stakeholder confidence. A structured change management process is essential for maintaining control over scope, timelines, and budgets. It ensures that all proposed changes are evaluated for their necessity, feasibility, and financial impact before implementation.

Effective change management begins with a clear policy outlining how changes are requested, reviewed, and approved. Regular communication with stakeholders is also critical to align expectations and address concerns. Digital tools can help track and document change requests, making it easier to assess their impact on the project’s overall goals.

Example:

A $700M petrochemical project implemented a formal change request system after $10M was lost to uncontrolled scope changes. The new system required detailed justification and impact assessments for each change, preventing further overruns.

8. Focusing on Construction Efficiency

Construction efficiency directly impacts project costs and timelines, making it a critical area for cost control. Techniques like modular construction and prefabrication significantly reduce on-site labor and minimize waste, leading to faster project completion. In addition, real-time monitoring tools such as drones and IoT devices help track progress and identify inefficiencies.

Workforce productivity is another key factor. Proper training programs, clear communication of expectations, and optimized resource allocation can boost efficiency while minimizing errors and accidents. By continuously seeking innovative construction techniques and technology, teams can save millions and meet deadlines without compromising quality.

Example:

A $1.2B LNG project saved $20M by adopting modular construction, reducing on-site labor by 30% and shortening the construction timeline.

9. Post-Project Auditing and Continuous Improvement

Post-project audits are invaluable for identifying inefficiencies, successes, and areas for improvement. These audits analyze key aspects of the project, such as cost performance, resource utilization, and risk management, to provide actionable insights. The findings not only help avoid repeating mistakes in future projects but also contribute to continuous improvement across the organization.

A thorough audit includes reviewing the accuracy of cost estimates, the effectiveness of procurement strategies, and the impact of change management decisions. Lessons learned are then documented in a centralized repository, creating a knowledge base for future teams.

Example:

An audit of a renewable energy project revealed $2M in logistics overages due to inefficient transport scheduling. Implementing a centralized logistics system for subsequent projects saved time and reduced costs.

10. Collaborating with Stakeholders

Stakeholder collaboration is vital for project success, especially in cost control. Misaligned expectations or poor communication can lead to delays, redesigns, or budget overruns. By engaging stakeholders early and maintaining open communication throughout the project, teams can build trust and ensure everyone is aligned on objectives.

Effective collaboration involves regular meetings, transparent reporting, and the use of collaboration platforms to share updates and resolve issues in real time. Proactively addressing stakeholder concerns minimizes misunderstandings and prevents costly disputes.

Example:

In a $1B pipeline project, stakeholder workshops identified and resolved design conflicts early, avoiding $25M in potential rework costs.

Conclusion

Cost control in energy projects is not a single action but a continuous effort requiring careful planning, proactive management, and collaboration across teams. By implementing these ten strategies, project teams can mitigate risks, optimize resources, and ensure financial success while delivering high-quality outcomes.

Disclaimer

The information provided in this post is for reference purposes only and is intended to serve as a guide to highlight key topics, considerations, and best practices. It does not constitute professional advice or a substitute for consulting regarding specific projects or circumstances. Readers are encouraged to evaluate their unique project needs and seek tailored advice where necessary. Please Contact Us to discuss your particular project.