Estimating is the backbone of successful project planning and execution, especially in energy projects where the stakes are high and the margin for error is narrow. Selecting the right estimating methodology is critical, as it directly impacts budgeting, scheduling, and decision-making throughout the project lifecycle. Each estimating methodology offers distinct advantages and is suited for different project types, phases, and levels of information availability.

This article provides a comprehensive comparison of the most widely used estimating methodologies, highlighting their applications, strengths, and limitations. By the end, you’ll understand how to select and implement the best approach for your next project.

What Are Estimating Methodologies?

Estimating methodologies are systematic approaches used to predict the costs of a project. These methodologies vary based on the level of detail, the data available, and the purpose of the estimate. They can broadly be categorized into three main types:

Additionally, hybrid approaches and emerging technologies are reshaping traditional estimating processes.

1. Analogous Estimating

Analogous estimating, also known as comparative estimating, uses data from past projects to predict costs for a new project. This method relies heavily on historical data and expert judgment.

Applications

- Early project phases when detailed information is unavailable.

- Projects with similar scopes, locations, or specifications to previously completed projects.

- Feasibility studies or conceptual estimates.

Process

- Identify a similar completed project.

- Adjust costs based on differences in size, scope, complexity, or market conditions.

- Use expert input to refine the estimate further.

Strengths

- Quick and Cost-Effective: Ideal for early-stage estimates when speed is critical.

- Simplicity: Easy to apply without extensive data or software.

- Benchmarking Opportunity: Encourages organizations to maintain and utilize historical project databases.

Limitations

- Subjectivity: Heavy reliance on expert judgment can introduce bias.

- Accuracy: Less precise than other methods, especially if project-specific factors differ significantly from the reference project.

- Data Dependency: Requires access to reliable and relevant historical data.

Example

If a similar pipeline project cost $50 million to build in a neighboring region, an analogous estimate might adjust for regional labor costs, inflation, and updated material prices to arrive at an estimated cost for the new project.

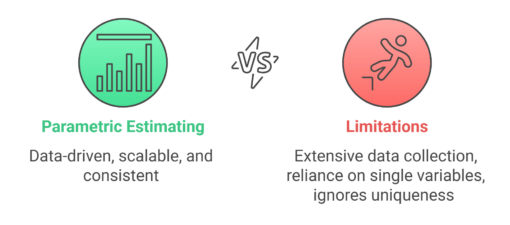

2. Parametric Estimating

Parametric estimating involves using statistical models to calculate costs based on key project parameters or metrics. This methodology is data-driven and relies on the establishment of cost-per-unit factors.

Applications

- Projects with quantifiable, repetitive components (e.g., roads, pipelines, or modular buildings).

- Mid-level estimates requiring greater detail than analogous methods but less effort than bottom-up approaches.

Process

- Identify critical parameters (e.g., square footage, pipeline length, or production capacity).

- Apply cost-per-unit factors derived from historical data or industry benchmarks.

- Adjust for market conditions, location, and other variables.

Strengths

- Consistency: Reduces subjectivity by relying on mathematical relationships.

- Scalability: Easily adjusted for different project sizes or volumes.

- Accuracy: More precise than analogous estimating, particularly for projects with well-defined parameters.

Limitations

- Complexity: Requires robust data collection and statistical analysis.

- Applicability: Not suitable for projects with unique or complex characteristics.

- Risk of Oversimplification: Over-reliance on a single parameter can lead to inaccuracies.

Example

For a wind farm, a parametric model might use the cost-per-megawatt of generating capacity (e.g., $1.2 million/MW) to estimate total project costs based on the planned capacity (e.g., 100 MW x $1.2 million/MW = $120 million).

3. Bottom-Up Estimating

Bottom-up estimating, often called detailed estimating, builds the total project estimate from individual cost components. This method involves breaking the project into smaller elements (work packages) and estimating each in detail.

Applications

- Projects in advanced planning or execution phases with well-defined scopes.

- Complex projects requiring high levels of accuracy.

- Contracts with fixed-price or cost-plus arrangements where cost precision is crucial.

Process

- Break the project scope into smaller components, such as tasks or work packages.

- Estimate costs for each component, including labor, materials, equipment, and overhead.

- Aggregate all component estimates to arrive at the total project cost.

Strengths

- High Accuracy: Provides the most detailed and precise estimates.

- Transparency: Clear breakdown of costs aids in tracking and accountability.

- Customizability: Tailored to the unique requirements of each project.

Limitations

- Time-Consuming: Requires significant effort and resources.

- Data Dependency: Relies on detailed designs, schedules, and resource plans.

- Complexity: Challenging to manage for large-scale projects without robust tools and processes.

Example

For a refinery upgrade, bottom-up estimating would calculate costs for each activity (e.g., equipment installation, pipe welding) and aggregate them into the total project cost.

Hybrid Approaches

In practice, many projects combine estimating methodologies to balance accuracy and efficiency. Hybrid approaches tailor the methodology to different phases of the project or parts of the scope.

Applications

- Projects with varying levels of detail available across phases or work packages.

- Estimates requiring quick initial numbers followed by refinement over time.

Examples

- Conceptual Phase: Use analogous estimating for early-stage feasibility studies.

- Design Phase: Apply parametric estimating for elements like square footage or capacity.

- Execution Phase: Employ bottom-up estimating for detailed construction plans.

Advantages

- Flexibility: Adapts to the evolving project scope and available information.

- Efficiency: Focuses resources where they are needed most.

Emerging Trends in Estimating

Data-Driven Estimating

With the rise of big data and advanced analytics, estimating is becoming more precise and predictive. Organizations are leveraging historical databases, real-time data, and predictive models to improve estimating accuracy.

Artificial Intelligence (AI) and Machine Learning

AI tools can identify patterns in historical data, automate repetitive tasks, and provide insights into risks or opportunities. These technologies are particularly useful for parametric estimating and hybrid approaches.

Integrated Project Delivery (IPD)

IPD methodologies encourage collaboration between owners, contractors, and engineers to create shared estimates, reducing redundancies and improving transparency.

Cloud-Based Estimating Tools

Software like Procore, Primavera, or BIM 360 allows teams to access, share, and update estimates in real-time, ensuring alignment across stakeholders.

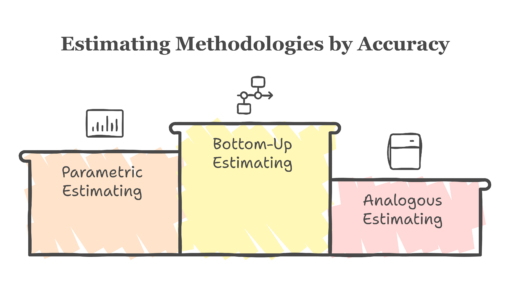

Comparing the Methodologies: A Summary

Criterion | Analogous Estimating | Parametric Estimating | Bottom-Up Estimating |

Accuracy | Low to Medium | Medium to High | High |

Time Requirement | Low | Medium | High |

Data Dependency | Historical data | Statistical models and benchmarks | Detailed project data |

Project Phase | Early | Mid | Advanced |

Complexity | Simple | Moderate | Complex |

Best Use Case | Feasibility studies, conceptual estimates | Repetitive or scalable project components | Detailed construction or execution plans |

How to Select the Right Estimating Methodology

Selecting the right estimating methodology depends on several factors:

- Project Phase: Use analogous or parametric methods during early stages and switch to bottom-up as the project progresses.

- Available Data: Ensure the methodology aligns with the level of detail in the project’s scope and design.

- Accuracy Requirements: Balance the need for precision with resource availability and time constraints.

- Project Complexity: Tailor the approach to the project’s uniqueness, size, and complexity.

Conclusion

Estimating methodologies are not one-size-fits-all solutions. Each approach analogous, parametric, bottom-up, or hybrid offers distinct benefits and is suited to different project scenarios. By understanding their applications, strengths, and limitations, project teams can make informed decisions to develop accurate and reliable estimates.

In the rapidly evolving landscape of large-scale industrial projects, leveraging the right estimating methodology and combining it with emerging technologies like AI and data analytics can be the difference between project success and failure. An effective estimating process is not just a financial tool; it is a strategic asset that guides every aspect of project execution.

Disclaimer

The information provided in this post is for reference purposes only and is intended to serve as a guide to highlight key topics, considerations, and best practices. It does not constitute professional advice or a substitute for consulting regarding specific projects or circumstances. Readers are encouraged to evaluate their unique project needs and seek tailored advice where necessary. Please Contact Us to discuss your particular project.